-

Highlight

hot melt rat glue trap making machine

,18.5KW rat glue trap making machine

,rat trap machine 18.5KW

-

Product NameFly Sticky Trap Machine

-

FunctionGlue, Conbined ,cutting,counting

-

Rewinder Size1100*1000*900 Mm

-

Glue Tank Size1100 * 560 * 1050 Mm

-

Counting Extension Size2000 * 985 * (700-950 Mm )

-

Heat Power15 KW

-

Total Power18.5KW

-

Work Speed 120000 Pcs / Hour ( Produce Sheet , Not Include Punch Speed )

-

Work Speed 210000 Ocs / Hour ( Produce Include Punch Speed)

-

Work Speed 33000 M / Hour ( Produce Rewind Coil Speed )

-

Place of OriginChina

-

Brand NameKingsun

-

CertificationCE ISO

-

Model NumberKS-pest

-

Minimum Order Quantity1

-

PriceNegotiation

-

Packaging Detailsplastic flim and wooden case

-

Delivery Time30 work days

-

Payment TermsT/T, Western Union, L/C, MoneyGram, D/A, D/P

-

Supply Ability30 sets per month

18.5kw Pest Control Hot Melt Rat Glue Trap Making Machine

Pest Control Glue Board Paper Insect Fly Sticky Trap Machine

1. The technical parameter of fly sticky trap machine

| Max coil width | 300 mm or special custom |

| Max glue width | 290 mm or special custom |

| Max coil diameter | 800mm ( advice 400-500 mm , easy to operation) |

| Coil inside diameter | 76mm |

2.The details of fly sticky trap machine

80 kg glue tank

Double gear pump

Double motor

Double frequency converter

Advantage :

Independently control each frequency converter, each motor and each gear pump.more stable and uniform for glue output .

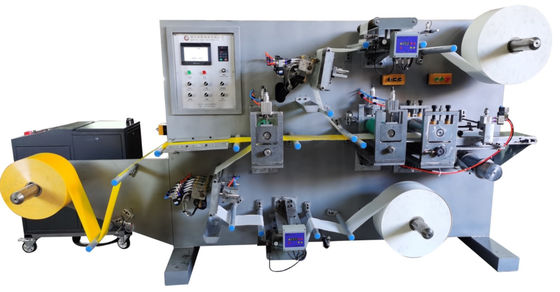

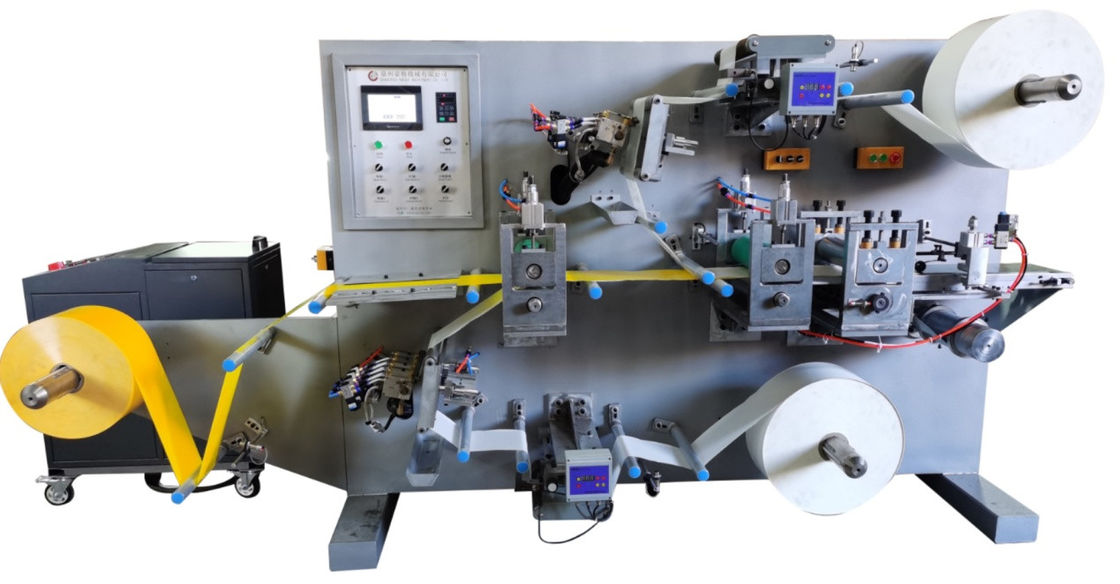

3.The photo of fly sticky trap machine

![]()

4.The Work Principle of fly sticky trap machine

(1) Through the transition wheel of the machine in turn,Install one roll of substrate and two rolls of release paper on the material roll of the machine, let the the main drive rubber wheel reaches the cutter.

(2) Two sets of glue guns apply glue on the release paper or silicone oil surface of the release film at the same time.

And the base material is laminated, and the cutter cuts it into single sheets according to the set length, and the finished product is punched through the punching device.