-

Highlight

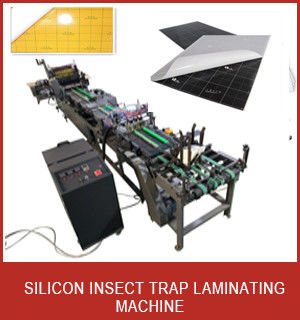

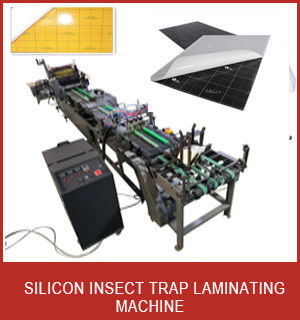

6000pcs rat glue trap making machine

,6000pcs rat glue trap machine

,310mm Rat Glue Trap Making Machine

-

UsageFor Cockroach , Insect Trap Board Make

-

ClassificationHot Melt Glue

-

Product NameAutoamtic Silicon Paper Laminator Insect Trap Board Machine

-

After-sales Service ProvidedEngineers Available To Service Machinery Overseas, Online Support, Video Technical Support, Field Maintenance And Repair Service, Field Installation

-

Speed6000pcs Per Hour

-

Place of Originchina

-

Brand Nameksapck

-

Model NumberHG838

-

Minimum Order Quantity1set

-

Price30000-50000

-

Packaging DetailsFULL CONTAINER , OR WOODEN BOX

-

Delivery Time30DAYS

-

Supply Ability5sets per month

310mm 6000pcs Per Hour Rat Glue Trap Making Machine

1)The feeding part can automatic or manual feeding .unit can remove when use the manual feeding style .

2)The machin process : auto feeding base paper( sheet style) –auto coating—auto lamination the silicon paper ( automatic cut the silicon paper to appropriate size )-finish ( there have the collect box in last of the machine)

3)hotmelt machine (80kg): put the glue in the melt machine ,automatic melting ,then across to glue hose sending to the glue gun coating the glue to the paper

4)silicon paper ( roller style ),after cut to need size sending to the adsorb laminating device ,then if the photoelectricity switch response the base paper come ,the stepper motor will take the silicon laminator with the base paper.

5)the production line totol length 5000mm

6) the max coating size :210mm

9)match with the HG880 style hot melt machine the capacity is 80kg

10)the machine have the cover guard in four side of the machine and also around the glue head.

11)the machine can adjust the glue coating quantity

12)the machine is plc control ,can show the capacity of products and the speed of per hour.

13) The machine to coat the glue as per samples sent with a moving tolerance of 2mm or less

14) At the end of machine there will be an extra movable conveyor of 1.5mtr so that the operator is away from the silicon roll.

| machine name | automatic silicon paper lamiantor machine |

| the work size | 210 or 310mm glue cost width |

| the glue tank size | 45kks |

| produce trap | cockroach , uv light insect trap , fly trap |

| the mahince size ; | 5800x1300x1820mm , |

![]()

![]()

![]()

![]()

![]()