Computer Control Rs4 Corrugation Machine Lead Adge Feeding For Corrugated Box

-

Highlight

rotary sheet cutting machine

,paper creasing machine

-

ColorAs The Customer Inquiry

-

Speed150 Pieces/min

-

ModelZLK

-

Apply ForCorrugated Carton Box Making

-

TypePackgae Machine

-

ApplicationMachinery & Hardware

-

Place of OriginChina

-

Brand NameKSPACK

-

CertificationCE/ ISO 9001

-

Model NumberZLK

-

Minimum Order Quantity1 set

-

PriceNegotiable

-

Packaging Detailsplatic film

-

Payment TermsD/A, D/P, L/C, T/T, Western Union

-

Supply Ability15 sets per month

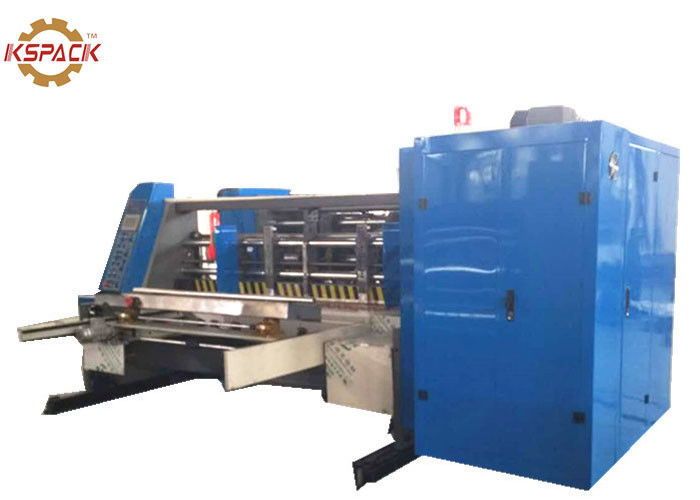

Computer Control Rs4 Corrugation Machine Lead Adge Feeding For Corrugated Box

Computer Control Lead Adge Feeding Rotary Slotter Machine For Corrugated Box

Characteristics :

Zlk series slotter adopt the internation advanced technicals,accumulate macinery the making experience design, high automatic ,high accurate ,high speed , and high reliable and safe as the designgoals ,combine the save energy , convenient operation and maintenance, humanized control need, meticulously. electrical components, drive bearing and pneumatic control components adopt international standards, fully reflects the high quality and stability of the machine, improve the service life of the machine, it is the ideal choice to you in the production of high quality carton

Performance:

1.the machine adopts computer control, phase adjustment and high adjustment are computer control electric box.

2.Front feeding system, vacuum adsorption transmission, suitable for all kinds of cardboard, add tissue paper board and bend cardboard transmission stability, high speed and precision.

3.High precision straight tooth gear, accurate and durable: 20 grmnti high-frequency quenching, grinding hardness HRC58-62, and up to the national level 6 precision, use for a long time, high accuracy. Cross roller drive structure, use for a long time no wear and tear, to ensure the transmission accuracy.

4 .From key connection mode, can make the shaft with gear, when used in high torque won't have clearance, installation and maintenance easy to change, improve the assembly accuracy, ensure the accuracy of overprint.

Technial Parameter :

| MODEL | ZLK-1200×(2000-3000) |

| MACHINE DESIGN SPEED | 170 |

| MACHINE WORK SPEED | 80—140 |

| MIN PASSING PAERSIZE | 380mm×650mm |

| MAX FEED IN SIZE (NORMAL FEEDING ) | 1200mm×(1700-2700)mm |

| MAX FEEDING SIZE (SKEP FEED ) | 1400mm×(1700-2700)mm |

| MAX EFFECTIVE SLOT AREA | 1200mm×2200mm |

| MIN SLOT GAP(POSITIVE AND negative ) | 260mm×100mm×260mm×100mm |

| Max slot depth | 530mm |

| Max corner cut size | 50mm |

| Max board thickness | 2mm-12mm |

Machine Picture :

![]()