Bydj-2600 Simple Automatic Box Stitching Machine Carton Box Fold Glue 1.5KW

-

Highlight

Simple Automatic Box Stitching Machine

,1.5KW Automatic Box Stitching Machine

-

ApplicationCarton Box Stitching

-

Dimensions1400*800*1400mm

-

Max. Stitch Pitch25mm

-

Max. Stitch Width25mm

-

Power1.5KW

-

Power Supply220V/50HZ

-

Product NameCarton Box Stitching Machine

-

Stitch Length2-4mm

-

Stitch MaterialAluminum, Steel, Copper

-

Stitch Pitch2-4mm

-

Stitch Speed3000-4000/min

-

Stitch Thickness2-4mm

-

Stitch Width2-4mm

-

TypeAutomatic

-

Weight200KG

-

Place of OriginCHINA

-

Brand NameKSPACK

-

CertificationCE ISO

-

Model NumberKSJ

-

Minimum Order Quantity1SET

-

PriceNegotiate

-

Delivery Time5-8 Work Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union

-

Supply Ability1 set per 20 days

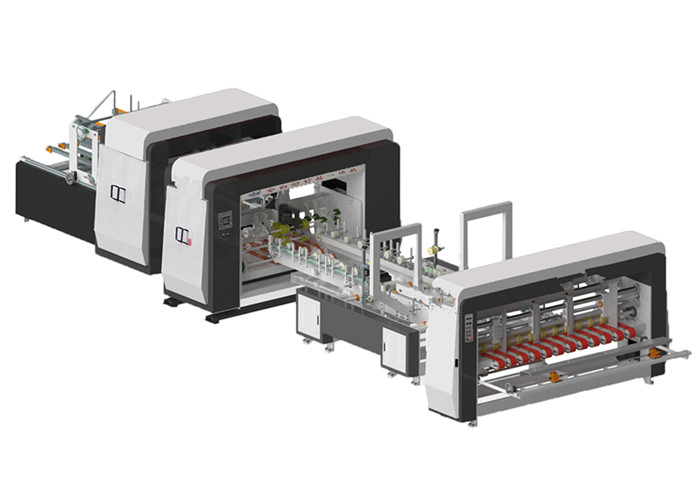

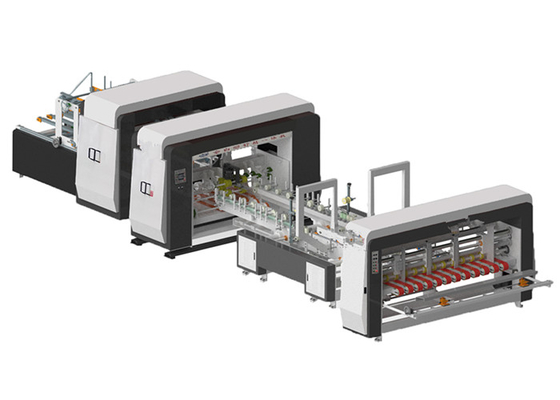

Bydj-2600 Simple Automatic Box Stitching Machine Carton Box Fold Glue 1.5KW

Bydj-2600 Simple Automatic Box Stitching Machine Carton Box Fold Glue

1,Carton Box Stitching Machine Description:

The compact automatic stapling and gluing machine is composed of a paper feeding section, a folding section, a nail box section, a counting output section, and an electrical control section. The device uses PLC control and touch screen input of data. The operation of the nail box is controlled by a servo motor, thus providing a reliable, simple and effective operation. The machine features automatic paper feeding, automatic folding, automatic correction, automatic nailing, automatic counting, automatic stacking output, and synchronization adjustment before and after the completion of the entire operation. The device also facilitates the storage of orders and the identification of any defects in the clamping and nail setting operations. This makes adjustments more convenient, quick and efficient. The device uses advanced technology and exhibits a high level of reliability.

2,Carton Box Stitching Machine Specifications:

| Model and parameters | QDJ-2600(No beat) | QDJ-2600(No beat) |

| Maximum size(A+B)X2(mm) | 2400mm(stick)2600mm(nail) | 2600mm |

| Minimum size(A+B)X2(mm) | 780mm | 1060mm |

| Maximum size(C+D+C)(mm) | 1000mm | 1000mm |

| Minimum size(C+D+C)(mm) | 340mm | 510mm |

| Minimum swing cover C(mm) | 25mm | 25mm |

| Maximum swing cover C(mm) | 320mm | 320mm |

| Maximum width B(mm) | 480mm | 480mm |

| Minimum width B(mm) | 165mm(nail)140mm(stick)(stick) | 250mm |

| Maximum length A(mm) | 820mm | 820mm |

| Overall power(kw) | 20kw | 20kw |

| Minimum length A(mm) | 200mm | 280mm |

| Maximum height D(mm) | 650mm | 650mm |

| Minimum height D(mm) | 200mm | 200mm |

| Nail tongue width E(mm) | 30-35mm | 30-35mm |

| Mechanical length(mm) | 12000mm | 12000mm |

| Mechanical width(mm) | 3500mm | 3500mm |

| Mechanical weight(T) | 7.5T | 7.5T |

| Mechanical speed(Nail / min) | 600 Nail / min | 600 Nail / min |

| Order number | 1-99 | 1-99 |

| Nail pitch(mm) | 30-80mm | 30-80mm |

| Nail box speed | 55 M / min | 55 M / min |

| Gluing speed | 80 M / min | 80 M / min |

3,Carton Box Stitching Machine Feature Advantage:

A,Paper feed section:

The main motor adopts frequency conversion speed regulation, the system has no noise, and the speed regulation is flexible and stable.

The imported porous skin is used for conveying paperboard, which is stable, efficient and accurate.

The paper feeding section can be electrically adjusted to meet the paper supply requirements of various specifications of cartons, which is convenient and fast.

It is equipped with side flapping device to ensure paper feeding is not skew.

B,Folding part

Linkage with the paper feeding section, frequency control, folding and paper feeding section line pressing synchronous adjustment.

The imported porous belt is used to transport the paperboard, with automatic folding and full adsorption, which can effectively avoid the skew, slipping and stacking phenomenon of various paperboards such as weighting box, laminating box and polishing box, so as to make the whole machine more stable and efficient.

C,Correction unit

There will be a shaping device behind the folding part and in front of the nailing box. In front of the nailing box, the folded carton will be reshaped and photographed again to ensure that there is no scissors opening for the nailed carton.

The calibration unit is driven by servo motor.

D,Nail box

The head of nail box is made of special material, which is wearable and not easy to be damaged.

The characteristic of this machine is that the head is driven directly by servo motor, and the speed is stable and accurate.

Two sets of 20kg large plate flat wire automatic feeding device are used in the nailing line, which can reduce the number of wire changing and improve the production efficiency.

This machine can carry out multi-function operation of single nail, double nail, reinforcing nail and head and tail nail.

The nail speed can reach 600 nails per minute.

E,Counting and stacking output unit

Complete the carton, and then pat, count, stack and send out the carton automatically.

4,Our Company

We are a professional supplier of corrugated machinery,including automatic high speed flexo printer slotter die cutters,corrugated board production lines,Rotary die cutters, carton staplers and two ply corrugated board production lines.Along with our development,we have set up our own factories. We are now enlarging our product area to testing equipment and other kinds of packaging machinery. Our products are widely used in various industries such as printing, packaging, food, beverage, pharmaceutical, cosmetic and so on. We have a strong R&D team and a strict quality control system to ensure the performance and reliability of our products. We also offer after-sales service and technical support to our customers.

5,Picture

![]()