High Speed Corrugated Box Printing Machine With Folding Gluing Line

-

Highlight

Corrugated Box Printing Machine 180 Sheets/min

,Corrugated Box Printing Machine High Speed

,Corrugated Box Printing Machine 120 Sheets/min

-

Speed120-180 Sheets/min

-

ColorCustomize

-

FunctionCarton Printing Slotting

-

Colors1-4 Colors

-

Printing MaterialCorrugated Cardboard

-

NameCorrugated Box Printing Machine

-

Place of OriginCHINA

-

Brand NameKSPACK

-

CertificationCE ISO

-

Model NumberKSJG

-

Minimum Order Quantity1 SET

-

PriceNegotiate

-

Delivery Time5-8 work days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Supply Ability1 set per 30 days

High Speed Corrugated Box Printing Machine With Folding Gluing Line

High Speed Corrugated Box Printing Machine With Folding Gluing Line

Printing Section(Description)

Lead Edge Feeder Unit

1Machine clutch

The electric control platform is accompanied by an alarm bell, and the alarm is continuously sounded during the movement. for ensure the safety of operators. The transmission shaft is equipped with a safety clutch to avoid malfunction and damage the machine (when the machine platform is not locked, the main engine cannot start operation). With pneumatic interlocking device. With main motor start protection device.

2Adsorption lead edge feeding system

The lead edge feed mechanism can minimize the jamming in the paper feeding process at the greatest extent. The suction blower assists the feeding of paper. to ensure that the curved paperboard is smoothly fed in. The air volume can be adjusted according to the size of the paperboard, and the vacuum suction force of the paperboard can be ensured to the utmost so as to make the paper feeding more accurate. The front dam-board and the rear dam-board adopt manual adjustment gaps, and the left and right side dam-board of the paper feed are electrically adjust gaps. The feed wheel is made of polyurethane material, which has high friction and long service life. Feeding rubber wheel open joint structure, easy to change. Suitable for three, five, seven layers of corrugated cardboard, including E-flute corrugated cardboard. Paper counter, setting, display the production quantity.

3Dust extraction device

Equipped with a dust extraction mechanism (dust extraction brush and vacuum suction fan) to effectively remove paperboard surface impurities and improve, to improve printing quality.

4Paper feeding roller

The outer diameter is Ф154.3mm. Seamless steel pipe, wrapped with wear-resistant rubber, and after balance correction process. Under roller with chrome plating. Paper feeding roller up and down electrical adjustment range 0-12mm.

5Operation control switch (PLC computer control)

The control panel is equipped with a 10-inch touch screen, which can control the Lead edge feeding unit, printing unit, slotting unit, die cutting unit, and is easy to operate.

6Automatic zero device

The lead edge feeding unit, printing unit, slotting unit, and die cutting unit are automatically zeroed electrically. Normally, automatic zeroing device is used for the carton. After test print second cardboard, it can be adjusted to the correct position to reduce paperboard waste.

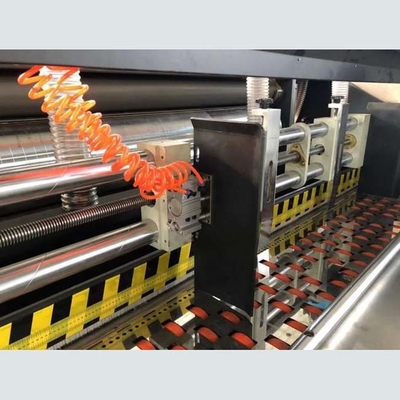

Printing Unit

1Printing roller

The outer diameter: Ф586 mm (including the plate diameter Ф600mm). Material: steel plate, surface grinding, hard chrome plating. After dynamic balance correction process, smooth operation. Ratchet fixed scroll shaft. Full-version plate groove, Use for thickness 9mm hanging plate. Loading and unloading printing plate, electric control positive and negative by pedal switch.

2Printing pressure roller

The outer diameter: Ф159mm. Steel pipe surface after grinding and hard chrome plating. After dynamic balance correction, smooth operation. Printing press roller up and down electrical adjustment range: 0-12mm. Feeding roller up and down electrical adjustment range: 0-12mm.

3Ceramic anilox roller

The outer diameter: Ф219 mm. Ceramic roll surface adopt high technology laser engraving treatment which is hard and smooth. The anilox are the same and the ink is uniform. Prolong the life of printing plate and rubber roller. Adjustment of the anilox roller gap dial by manually.

4Rubber roller

The outer diameter: Ф202mm.The surface of steel pipe is wrapped with wear-resistant rubber. High special grinding in the rubber roller, ink transfer wonderful effect.

5Feeding up/down roller

Upper roller: Out diameter: 110mm, seamless steel tube with 2 feed wheel. Wheel is 2 piece joint. Down roller: Out diameter:154.3 mm, seamless steel pipe, surface grinding, hard chrome plating. Adjust the paper feed roller gap dial electrical adjustment. adjust range of 0-12mm.

6Phase adjustment mechanism

Planetary gear construction. Horizontal position, manually adjust the distance. Total: 20mm. The printing roller adopts frequency converter to adjust the phase, return to zero and adjust the printing speed, and the adjustment accuracy is high.

7Ink circulation

Pneumatic diaphragm pump, ink supply stable, easy to operation and maintenance. Ink filter, filter impurities.

8Printing phase fixture

Pneumatic brake mechanism. When the machine operate or adjusts the phase, the brake mechanism restricts the rotation of the machine and maintains the fixed position of the original gear position.

9Safety measures: Between each unit there is an emergency pull switch.

Slotting Unit

With self-locking function, The pr-pressing quick adjustment mechanism ensures the long-term accuracy between the disc and the shaft, and slows the breakage of the paper when pressing the line. The creasing line wheel adopts the latest design of pr-pressing type, to protect the cardboard flatness. All Pr-creasing and creasing wheel 2 piece joint structure. It is equipped with PLC programmable control to synchronize the axial movement of the left and right synchronous transport, so that the upper and lower creasing wheel, upper and lower slotter knife, synchronous adjustment, adjust the box height by electrical, and with memory storage function. Planetary gear-type phase adjustment mechanism with digital display function for electric adjustment of slotted phase and slotted box height. Adopt high-quality alloy steel slotting knife, tooth blade width: 7mm.

With the lubricating and wear-resistant guide block, to ensure the correct displacement of the pinch roller and the slotted knife wheel and increase the durability. Equip with trim edge cutting knife to ensure the accuracy of box size.

1Operation control

Installed the touch screen, automatically detect and adjust through the PLC and rotary encoder, and call up the storage menu. The automatic alignment is fast and efficient. Use electric control switch to adjust the axial, longitudinal and box height dimensions of each knife holder. Use the quick clearance fine-tuning self-locking device for the paper gap. Equipped with emergency stop device to ensure safety.

2. Slotting phase/box height adjustment:

The slotting phase is 360° positive and negative adjustment, fast, high precision. The phase zeroing device ensures the consistency of the slotting position. The adjustment of the box height adopts the electric adjustment of the internal tooth structure to prevent the gear oil contaminating the cardboard. Adjust the knife by computer automatically and correction automatically.

Creasing wheel

High-strength creasing wheel, diameter: Φ110mm, hard chrome plated on the surface. Creasing wheel 2 piece joint structure easy to change. Adjust the axial position of the pinch roller and the slotter knife head synchronously.

3. Paper slitting/Slotting knife

The thickness of the slotter knife: 7mm. The high-quality alloy steel heat treatment tooth-shaped slotting machine is manufactured by professional manufacturers to ensure the quality. The shaft diameter: Φ159mm. The surface is chrome-plated and moves smoothly. Automatically adjust the position of the slot, paper slitter, creasing wheel, and preload wheel axially. The slotting middle knife can move, suitable for producing large-size and double-piece box. Adopt a unique projectile chip removal device, reduces costs and has a long life. Groove interval, box height, PLC and rotary encoder control, automatic adjustment. Store up to 100 orders, accurate and efficient automatic alignment.

Rotary Die Cutting Unit

1. The roller is made of hard chrome plated on the surface, material is high-quality steel, After dynamic balance correction, to increase its operating stability and reliability.

2. Die roller and soft roller made by international standard size, die roller diameter: 550mm, plus wooden die diameter: 600mm, soft roll diameter is 434.2mm (excellent rubber sleeve outside diameter 550mm), can be purchase the wooden die and rubber anywhere.

3. Adjust the gap between the die cutter roller and the rubber roller by electrical adjustment.

4. The phase of the die-cutting roller adopts a three-planetary structure, which has high precision and large bearing capacity. The stop and operation can be adjusted by electric digital 360°.

5. When the paper feed stop, the soft roll rises automatically, reduce the wear of the soft roll.

6. The rubber is made of polyurethane felt cover Germany Dipair brand, which can achieve 100% cutting rate. The incision is smooth. The replacement order of the rubber pad shall be based on the loading and unloading operation manual of the rubber pad.

7. The rubber pad roller adopts the mechanical cam type left and right movement (30mm) device, each knife is in different positions, effectively extending the service life of the felt sleeve.

8. Die cutting upper and lower rollers have different diameters, but the two rollers have the same linear velocity. It can control the infinitely non-circulating work of the die cutter in the circumferential direction, making the wear of the rubber sleeve more uniform.

9. With line speed compensation device, when the soft roller diameter changes, the line speed automatic compensation device automatically track compensation, without manual adjust the speed, to ensure that the size of each batch of cardboard boxes die-cutting is exactly the same, while greatly extending the felt and knife mold life.

10.The soft roll automatic repair device can repair the worn felt cover several times. The repaired felt cover is smooth and clean, and maintains the same performance as the new felt cover. Greatly increase the reusability of felt mats.

11.Die cutting lower cylinder equip ring slotting knife, the lower roller can electrical move left and right ±10mm.

12 . Die cutting unit have control panel for paper feed opening/closing and host electric button, with multi-point adjustment operation function.

Printing Machine Main Parameter

| No. | 参数名称 Parameter | 单位 Unit | Details |

| 1 | 机械内侧宽度 Machine size(inner side) | mm | 3000 |

| 2 | 设 计 速 度 Max. Design speed | pieces/min | 180 |

| 3 | 经济运行速度 Economical speed | pieces/min | 50-150 |

| 4 | 最大进纸尺寸 Max. Paper Feeding size | mm | 1650×2800 |

| 5 | 最小进纸尺寸 Min. Paper feeding size | mm | 400×700 |

| 6 | 最大印刷面积 Max. Printing size | mm | 1650×2600 |

| 7 | 隔张进纸尺寸 Skip paper feeding size | mm | 1800×2800 |

| 8 | 套色精度 Precision of printing | mm | ±0.7 |

| 9 |

标准印版厚度 Standard print plate thickness |

mm | 7.2 |

| 10 | 适应纸板厚度 Paperboard thickness | mm | 2-10 |

| 11 | 最小开槽间隔 Min.slotting distance | mm | 180*180*180*180mm |

| 12 | 最小开槽箱高 Min. Slotting Box height | mm | 100 |

| 13 | 最大模切面积 Max. Die cutting size | mm | 1650×2700 |

| 14 | 模切纸板厚度 Die cutting paperboard thickness | mm | 2-10 |

| 15 | 印刷滚筒轴向调节 Print roller axial direction adjustment | mm | ±10 |

| 16 | 刀模滚筒轴向调节 Die molds cylinder axial direction adjustment | Mm | ±10 |

Folding Gluing Part

Folder Gluer Main Technical Parameters

| 序号 No. | 参数名称 Parameter | 单位 Unit | 规格 Size |

| 1 | 设计速度 Design speed |

米/分 m/min |

200 |

| 2 | 经济速度Economical speed |

米/分 m/min |

150-180 |

| 3 |

最大进纸尺寸 Maximum feeding size |

mm | 1650×2800 |

| 4 |

最小进纸尺寸 Minimum feeding size |

mm | 400×700 |

| 5 |

纸板厚度 Paperboard thickness |

mm | 2-10 |

| 6 | 粘箱误差precision of glue | mm | ±2 |

| 7 |

粘箱剪刀口误差 Precision of glue fish tail |

mm | ±2 |

| 8 |

总电机功率 Total power |

kw | 35 |

| 9 |

体积长宽高 Machine dimension |

mm | 16000x4500x3200 |

Material use

1.sprocket gear is made of 45# and 40Cr alloy steel, which is processed by quenching, grinding and high-frequency processing.

2.smooth operation, low noise, hardness hrc55-65, long life, small wear, can ensure long-term accuracy unchanged.

3.board drive adopts suction belt drive.

4.the belt drive shaft is made of 45# steel by tempering and tempering treatment, fine turning, fine grinding and electroplating.

5.The main wallboard is made of 30mm steel plate, which is processed by tempering and tempering, so that the machine runs smoothly and the wallboard does not deform

6.the connecting bar is welded with 220mm national standard channel steel, so that the machine runs stably and without vibration.

7.the left and right walking track is made of 30MM steel plate track, which is processed by tempering and tempering, and the walking is stable without deformation.

8.the paper folding upper cantilever is made of 35mm thick steel plate through tempering and finishing.

9.the paper folding lower cantilever is made of 35mm thick steel plate through tempering and finishing.

10.the board is transported by the upper suction belt, and the lower roller is passively transported. The design structure adopts Japanese mitsubishi technology.

11.Left and right origami beam walking axis, using guide shaft with diameter of 168mm sliding, support strength, stable operation of the machine, no deformation.

12.Tidy counting department frame adopt 280mm national standard channel steel welded.

13.Box conveying model use mechanical belt transfer type.

![]()