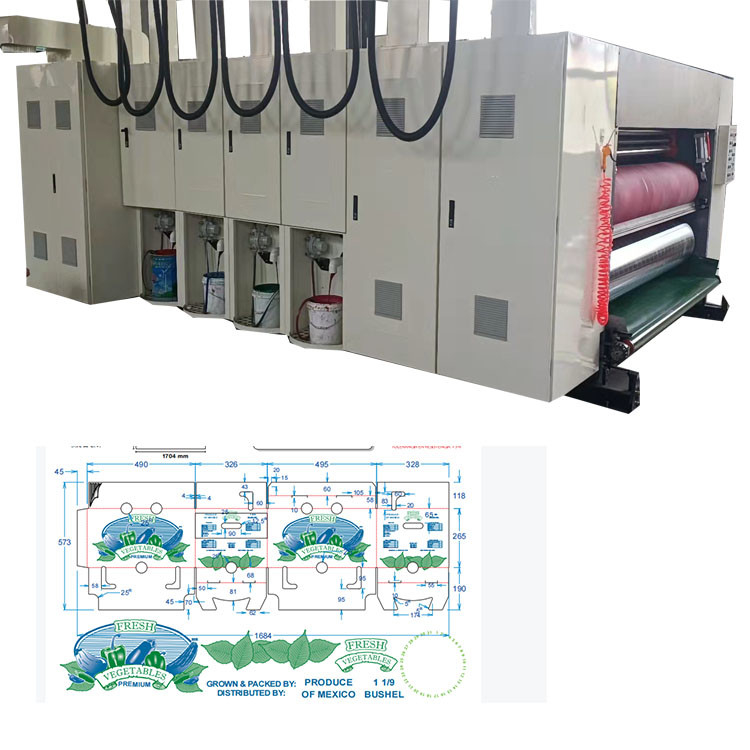

automatic high speed printer slotter diecutter stacker& vibration machinery

-

Highlight

5colors carton printing slotting machine

,plc carton printing slotting machine

,plc flexo printing slotting machine

-

NameAutomatic High Speed Printer Slotter Diecutter Stacker& Vibration Machinery

-

Colors1-5colors

-

InkWater Ink

-

Print Roller300-800mm

-

Roller Material;Steel And Ceramic Anilox

-

Feeding UnitLead Edge Feeder

-

Box TypeStandard Boxes

-

Place of OriginChina

-

Brand NameKSPACK

-

CertificationISO,CE

-

Model NumberKYM

-

Minimum Order Quantity1set

-

Price10000-100000usd/set

-

Packaging Detailswooden case

-

Delivery Time50days /month

-

Payment TermsL/C, D/A, D/P, T/T, Western Union

-

Supply Ability30sets

automatic high speed printer slotter diecutter stacker& vibration machinery

automatic high speed printer slotter diecutter stacker& vibration machinery

![]()

ü Gluing part: The non-stop method or the gluing system of the gluing part is used to avoid easy adjustment of the glue curing rubber wheel gap. The dial is suitable for paperboard with a thickness of between 1 and 9 mm. The amount of glue applied is easy to adjust.

ü In order to improve the speed of the belt speed bridge and flexographic printing slot production speed adjustment. At the same time, the folding belt, the conveyor belt produces a flexographic printing slotting speed almost the same, to avoid the folder and the water-based printing slotted parts are not synchronized, which may cause the cardboard to jam and achieve accurate delivery.

ü The upper and lower belt speeds can be adjusted separately, ie their speeds are different and can be adjusted to the same speed.

ü The folding cardboard adopts a belt or rubber roller to facilitate the adjustment of the folding angle.

ü The paper feed section uses spring pressure to adjust the gap, and the thickness of the cardboard is automatically adjusted between 1 and 9 mm.

ü Cardboard stacking and counting pieces.

ü The stack of cardboard is mechanically and sensorized for full automation.

ü The counter (sensor) counts the number of cartons for easy setup and reliability.

ü The stack of cardboard uses computer counting and precise pushing.

| Maximum mechanical speed (pieces/S) | 260 |

| Inside width of the machine (mm) | 2800 |

| Maximum continuous feeding size (mm) | 1400*2800 |

| Maximum paper feeding size of each sheet (mm) | 1600*2800 |

| Maximum printing size (mm) | 1400*600 |

| Minimum feeding size (mm) | 400*720 |

| Minimum slot size (mm) | 300*100*300*100 |

| Standard printing plate thickness (mm) | 7.2mm |

| Power during production (kw) | 33KW |

| Total power (kw) | 30KW |

| Wallboard thickness (mm) | 50 |

automatic high speed printer slotter diecutter stacker& vibration machinery

![]()