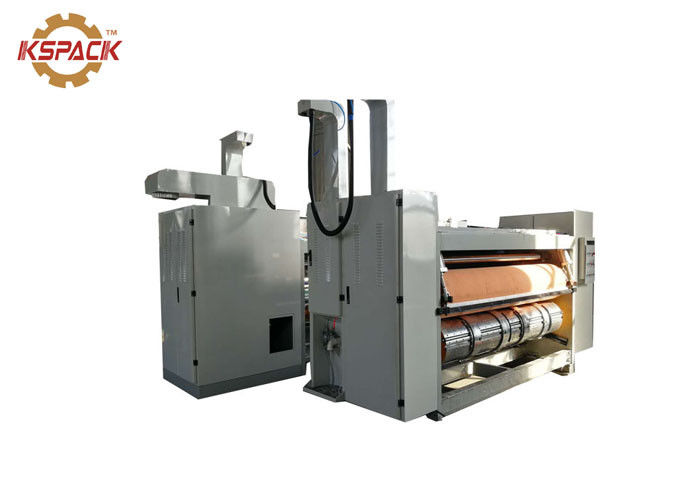

Automatic Corrugated Box Printing Machine , Cardboard Box Making Machine 1800mm Type

-

Highlight

two color flexo printing machine

,carton box making machine

-

Machine NameAutomatic Corrugated Box Printing Machine , Cardboard Box Making Machine 1800mm Type

-

ColorMulti Color

-

Speed150 Min

-

Voltage220V

-

FeatureConvenient Operation

-

Power7.5kw

-

Place of OriginChina

-

Brand NameKingsun

-

CertificationCE

-

Model NumberKSJ

-

Minimum Order Quantity1 Set

-

PriceNegotiate

-

Packaging DetailsPacking them in plastic wrap before putting them in wooden cases

-

Delivery Time20 work days

-

Payment TermsL/C, T/T, Western Union

-

Supply Ability5 set 40per days

Automatic Corrugated Box Printing Machine , Cardboard Box Making Machine 1800mm Type

Automatic Corrugated Box Printing Machine , Cardboard Box Making Machine 1800mm Type

Printing department

Printing roller

1) the outer diameter :400mm,

2) the steel tube surface grinding , hard chrome plating.

3) do balance correction, steady operation.

4) ratchet fixed volume edition axis.

5)full Plate Hanging plate slot, suitable for 9 mm plate of the article.

6) loading and unloading of the print plate , pedal switch of electric control forward and reversing.

2.The printing press roller

1) the outer diameter :156 mm.

2) the steel tube surface grinding , hard chrome plating.

3) do balance correction, steady operation.

4)the printing press roller gap dial manual adjustment,

adjustment range 0-12 mm .

3. Feeder paper up and down roller .

1) up roller, the outer diameter of:86 mm, thick wall steel pipe, with four feeder paper roller.

2)down roller,the outer diameter: 156 mm, thick wall steel

pipe, surface grinding, hard chromium plating.

3) paper roller gap dial manual adjustment, adjustment range

0-12 mm.

4.Steel anilox roller:

1) the outer diameter : 176 mm (mesh number: 200, 220

240, 220). (mesh optional)

2) steel pipe surface grinding, suppress anilox, hard chromium plating.

3) do balance correction, smooth and steady operation, lattice point is consistent, uniform inking.

4) anilox roller wedge type overrunning clutch, distributing, wash ink is convenient swift.

5) Anilox gap dial manually adjust.

5. Ceramic anilox roller (optional)

1) outside diameter is :176 mm.

2) steel tube surface coating ceramic grinding, laser engravinganilox.

3) anilox mesh for 260, 280, 320, 280. (mesh optional)

4) than steel anilox roller printing meticulously, wear-resisting, long service life.

SLOTTER PART :

1. The main body panels made of high quality cast iron, the large-scale machining center, precision work can finish it .

2. The main drive gear for helical gear, steel 45 # steel, precision plating, grinding high frequency quenching.

3. The drive roller for high quality 45 # steel, after grinding, hard chrome plating, etc.

4. Electrical appliances: main parts for schneider, Siemens and other imported components, to increase its stability, the main motor adopts the electromagnetic adjustable speed motor, high stability.

5.the knvies made of high quality, the forging, high frequency quenching process, precision machining, internal tooth type design (the teeth), the blade sharp and durable.

5.the four slot knvies with crease part same time adjustable

| Size | 2400mm(width) |

| Roller diameter |

400mm |

| Max feeder paper size | 1200x2200 |

|

Min feeder |

280x650 |

| Max printing area | 1200x2000 |

| Design speed (pcs/min ) | 100 |

|

Economic speed |

80 |

| Standard printing block thickness | 7mm |

| Main motor | 7.5kw |

| Air pump power | 7.5kw |

![]()