Semi Automated Electric Corrugated Carton Box Machine Paper Stapler Stitching Machine

-

Highlight

semi automatic stitching machine

,corrugated stitching machine

-

Product NameSemi-Auto Electric Corrugated Carton Box Paper Stapler Stitching Machine

-

Machine Width2850mm

-

Size2000mm

-

Automatic GradeSemi Automatic

-

Weight1.6T

-

Max High Of Feeder900mm

-

Place of OriginChina Hebei

-

Brand NameKingsun

-

CertificationCE

-

Model NumberBDJ

-

Minimum Order Quantity1 Set

-

PriceNegotiable

-

Packaging DetailsWrapped in plastic film and placed in wooden box

-

Delivery Time5-8 work days

-

Payment TermsL/C, T/T, Western Union

-

Supply Ability5 Set 30 per days

Semi Automated Electric Corrugated Carton Box Machine Paper Stapler Stitching Machine

Semi-Auto Electric Corrugated Carton Box Paper Stapler Stitching Machine

Semi-automatic nail box machine

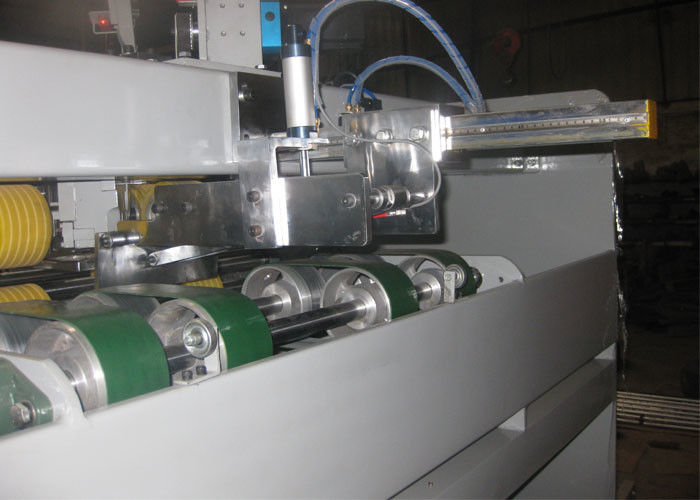

The two-piece nail box machine has a complicated structure and a full-featured function, and can be used for nailing a single-piece carton and a two-page forming carton. Below we will introduce the single-piece nail box machine, hoping to help everyone. Technical parameters Product name Model specification High-speed semi-automatic nail box machine (single piece) TJ-DA 1500*2400MM Cardboard conveying mechanism includes: upper and lower four transmission rubber wheels and paper feed rubber wheel, tailgate adjustment device, left and right bezel, transmission mechanism, etc. composition. The paper feed roller adjusts the gap with electric adjustment device, suitable for various types of different thickness cardboard. The nail head hybrid drive design combines the advantages of gearbox and chain drive for easy maintenance and maintenance, and low failure rate and high efficiency transmission.

1. Electronic control system: The color touch screen provides a good man-machine interface, completes the automatic setting of the nail distance, the setting of the nail and the cancellation, fault finding and so on. The LC programmable controller system is stable and reliable. The AC servo motor controls the paperboard to advance and stop, ensuring uniform and precise nail pitch.

2. Automatic counting light eye automatically counts and counts the output of the finished product, and can be set to separate and send out, and cooperate with the end machine of the latter stage.

3. The key to the nail box machine is the quality of the nail car and the nail head. The nail head is precision-developed with special steel, and the patented oscillating forming block is light and practical. Basic operation

4. Preparation process before nail box: Adjust the position of the main baffle according to the flap of the carton; adjust the position of the left and right baffles and the position of the upper and lower nail heads, pay attention to the fact that the left and right baffles cannot be clamped too tightly, and the cardboard should be inserted and pulled. Smooth out; after the mechanical adjustment is completed, the touch screen computer is set: Carton height = original carton height -40mm Carton pin number Carton nail distance Whether to strengthen the nail and other setting work single piece, double film selection above work is set, It is possible to carry out the nail box.

Machine specification

| Max size (A+B)X2 | 3600mm | min length A | 250 mm |

| Min size A+B)X2 | 740mm | Max height D | 2000 mm |

| Max size (C+D+C) | 3000mm | Min height D | 150 mm |

| Min size (C+D+C) | 250mm | Max flay size E | 40 mm |

| Min cover size C | 50mm | Max paper heigh | 900 mm |

| Max cover size C | 560 mm | Machine width | 2850 mm |

| Max width size B | 760 mm | Machine weight(T) | 2tons |

| Min width size B | 120 mm | Machine speed (nail/min) | 500 |

| Max length A | 1120 mm | Nail no. | 1-99 |

![]()