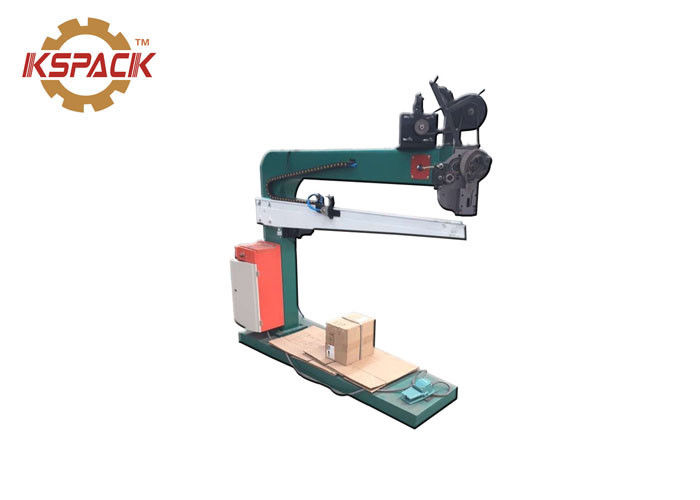

Manual Cardboard Carton Box Stitching Forming Stapler Machine

-

Highlight

automatic corrugated box making machine

,corrugated stitching machine

-

NameManual Cardboard Carton Box Stitching Forming Stapler Machine

-

FeatureHardness And Good Abrasion Resistance

-

Power3KW

-

FunctionCorrugated Carton Forming

-

Voltage220V-380V

-

AutomatizationManual

-

Place of OriginChina Hebei

-

Brand NameKingsun

-

CertificationCE

-

Model NumberGDJ

-

Minimum Order Quantity1 Set

-

PriceNegotiable

-

Packaging DetailsWrapped in plastic film and placed in wooden box

-

Delivery Time4-6 work days

-

Payment TermsL/C, T/T, Western Union

-

Supply Ability10 Set 20 per days

Manual Cardboard Carton Box Stitching Forming Stapler Machine

Manual Cardboard Carton Box Stitching Forming Stapler Machine

Construction:

The structure of the ordinary manual nail box machine is mainly composed of a nail head, a support arm, a drive motor, a transmission clutch, a body and a foot switch. The drive motor is generally 0.5 kW, using single-stage or two-stage V-belt transmission power, and has only one speed ratio to the motor. When the motor is running, the clutch does not move when the foot switch is not pressed, the nail head is not nailed, the nail box is needed, the cardboard is manually held, the switch is switched off, the nail head is actuated, and the nail is cycled. The more complicated part of this type of machine is the nail head and mechanical clutch. The most important part in the nose is the punch. As the punch reciprocates up and down, in a very short time (about half a second), the incoming line (including shearing) is pressed, pressed, and suspended. The design travel speed, acceleration and dwell time are different, the time required and the consumable parts are different, which brings difficulties to the manufacturer. The current reciprocating mechanism of the punch has three forms: a cam, an eccentric wheel and an eccentric shaft. The cam type is also called the groove wheel type. The disadvantage is that the machining is slightly difficult. The parts of the machine head are relatively more. Some wearing parts are small in material, but the steel must also be selected. The corresponding heat treatment process is used to improve the endurance and prolong the use. life. Regular maintenance should always be lubricated and kept clean. When purchasing such machines, the main thing is to look at the nail head and body of the manufacturer.

Installation requires editing

Before using the newly purchased nail box machine, you must carefully read the equipment instruction manual to understand the basic structure, performance and usage of the equipment to avoid the blindness of operation. When nailing the box, adjust the position of the main and left and right baffles and the position of the upper and lower nail heads according to the flap of the carton. When adjusting, it should be noted that the left and right baffles cannot be clamped too tightly, but the cardboard can be easily inserted and extracted easily. When the mechanical adjustment is completed, you can touch the screen to set the computer: carton height = original carton height -40mm, carton pin count, carton distance, whether to order reinforcement nails, single piece, double film selection, etc. Nail box can be made.

Main Parameter

| Model | Stapling Speed | Stapling Thickness | Stretching Length of the holding Arm | Exterior Dimension | Weight |

| DX-600 | 250 s/min | 3/5 ply | 600 mm | 1100x600x1760 | 300kg |

| DX-900 | 250 s/min | 3/5/7 ply | 900 mm | 1400x600x1760 | 400kg |

| DX-1200 | 250 s/min | 3/5/7 ply | 1200mm | 1700x700x1820 | 600kg |

| DX-1400 | 250 s/min | 3/5/7 ply | 1400mm | 1900x700x1820 | 800kg |

| DX-1800 | 250 s/min | 3/5/7 ply | 1800mm | 2300x700x1820 | 1000kg |

![]()

![]()