Corrugated Box Thin Blade Slitter Scorer Machine / Slitting Machine

-

Highlight

corrugated slitter machine

,slitter cutter creaser

-

Size Available1600-3000 Or Customized

-

Feeder TypeAutomatic Feeder

-

Shaft Qty8 Shaft Design

-

Machine FunctionFor Corrugated Box Making

-

Blade AdjustElectric Adjust

-

The Maximum Mechanical Speed150m/min

-

Place of OriginChina

-

Brand NameKS

-

CertificationCE,ISO

-

Model Number2800

-

Minimum Order Quantity1 Set

-

PriceNegotiable

-

Packaging Detailsmachine corvered with plastic sheet , packed in wooden case box

-

Delivery Time20 working days

-

Payment TermsD/A, L/C, T/T, D/P, Western Union, MoneyGram

-

Supply Ability30sets/month

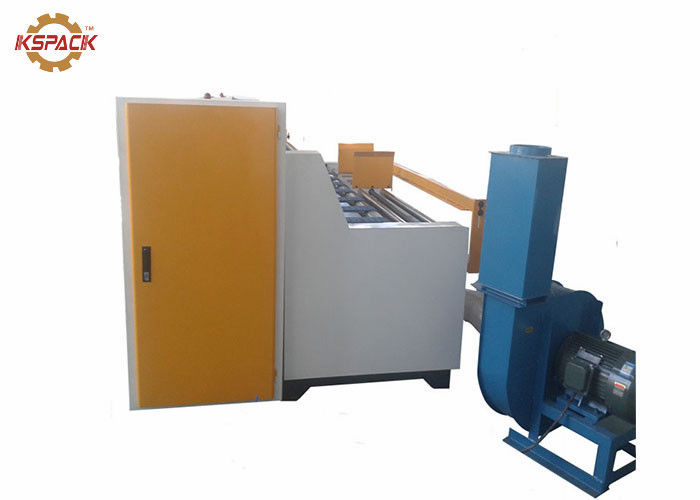

Corrugated Box Thin Blade Slitter Scorer Machine / Slitting Machine

Corrugated Box Thin Blade Slitter Scorer Machine / Slitting Machine

1.Machine Main Structure and Detailed Description

| Item | Description |

| Automatic feeder Department |

Cardboard size adjustment using screw adjustment mechanism, one person operation, easy and quick. |

| Slitting Department | 1)Thin knife slitting creasing machine adopts thin knife slitting, after grinding wheel after sharp blade makes cutting the cardboard edge finishing, flattening phenomenon is minimal, improve quality and appearance of cardboard overall quality especially in favor of cardboard printing after feeding, thereby reducing waste, improved quality of the carton. 2)Sharpener with manual and automatic switching of two ways, according to the time or paperboard running speed selection sharpener and stop grinding time. To keep the blade sharp and make cardboard cut smooth and tidy; 3)Adjust the blade from electric, pneumatic automatic locking fixation. Manually adjust the pressure line width. Using separate single-handedly carrying knives structure, according to the number of cardboard cut switch; program the machine wear and tear caused by different cutter size can be adjusted. Features: The plastic shaft feed, after cutting, and then plastic shaft feed, the last pressure line forming, after the process used when the clear indentation depth of cut paper with high steel knife blade drive belt drive, when replacing blades can be quickly set up for using plastic shaft pull paper, pull the paper toward the same equipment than the one higher than a chip. |

2. Main technology data

1. Specification:2000MM

2. Max. Cutting width:1900MM

3. Min. Cutting width:180mm

4. Adjustable height of creasing:0-12mm

5. Min. Creasing width:50mm

6. Motor power:4kw

7. Rotate speed: 0-1200turn/min

3.Features

1.Can set the qty. of paperboard, automatic stop the feeding after finishing.

2.Auto suction feeding, assured the safety of workers and decreased the working load.

3.Suitable to a large scale paperboard machining.

4.electric adjusted blades

4.Thin Blade Slitter Machine Pictures

![]()