Automatic Box Folder Gluer Machine With Vacuum Feeding PLC Control

-

Highlight

PLC Control Box Folder Gluer Machine

,Vacuum Feeding Box Folder Gluer Machine

-

Voltage380V

-

ConditionNew

-

Weight10T

-

TypeBoxes Folder And Gluer

-

After-sales Service ProvidedEngineers Available To Service Machinery Overseas

-

Automatic GradeAutomatic

-

Packaging TypeCase

-

ApplicationMachinery & Hardware

-

Packaging MaterialWood

-

NameBox Folder Gluer Machine

-

Place of OriginCHINA

-

Brand NameKSPACK

-

CertificationCE ISO

-

Model NumberKSJG

-

Minimum Order Quantity1 SET

-

PriceNegotiate

-

Delivery Time5-8 work days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Supply Ability1 set per 30 days

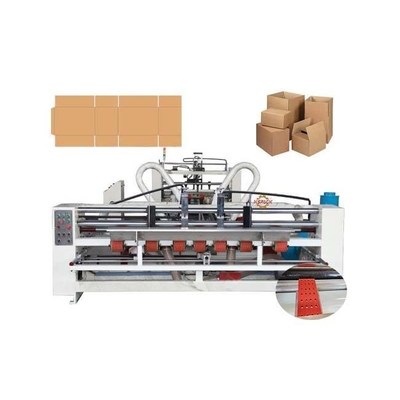

Automatic Box Folder Gluer Machine With Vacuum Feeding PLC Control

Automatic Box Folder Gluer Machine With Vacuum Feeding PLC Control

Box Folder Gluer Machine Description

Vacuum feeding section , glue and folding section ,counter and stacker section,PLC digital speed control,Remote speed control Touch screen control system for easy and Accurate operation.It can realize Automatic feeding, automatic folding and gluing, automatic counting, and automatic stacking output,Front and rear synchronous dual operation,Average speed is 120m/min, the maximum speed can reach 160m/min,With order storage memory function,Efficient energy conservation and environmental protection is our highest pursuit.

1. Automatic bending and coating.

2. Applicable carton wide range, different sizes carton adjustment is simple and quick.

3. The machine runs smoothly and reliably, the packaging effect is firm and beautiful.

4. Equipment operation is simple and easy to maintain.

5. With a separate pre-pressure wheel, solve the printing press line badproblem effectively. automatically correct the carton straight angle, effectively correct scissors fork, fish tail and so on.

6. Aseparate correction system can effectively control the carton scissors.

Easy touch screen opeation imput, whole machine adopt the plc computer programs controller , digital number operater, touch screen input the data, can be change the data, speed no need stop the machine, whole machine automatic supply the paper ,auto folder, auto counter, auto stacker, feed out, the speed 120m/min, max speed 160m/min.

Cardboard height adjustment structure,Choose high-quality steel , fast adjustment of a variety of box height and cardboard length. Paper suction Belt selection of high-tech materials, tensile layer seamless connecting, gurantee the machine use not have fault. Paper feed suction motor, main rotating motor are selected from Taiwan's high-quality, high stability motor. Choose high-grade electromagnetic clutch and electromagnetic brake system, so that the paper can be a single sheet or continuous operation, effective control cardboard waste. of the adjustment.

Motor choose import brand , Stable performance, convenient speed, no noise pollution. Folding part of the use of imported high friction, ultra-wear sp special materials made of seamless connecting conveyor belt, accurate and complete the automatic folding cardboard. Glue part choice high-quality stainless steel, even glue coat. save the glue. Folding Department is equipped with double-track correction device, accurate and effective correction of cardboard crease line deviation, so that the entire carton to complete the most accurate folding.

Motor choose import brand, stable automatic correction and stacking output have automatic counting, piled up neatly, stacking output, according to the customer demand can set up product box can do how much output, and automatically force calibration the scissors and other non-standard carton forming.

Spear part choose details

1.The whole machine uses 380V AC, power 11.5KW, energy saving and high efficiency.

2. PLC computer components, frequency conversion components, electrical components are selected from high quality imported components.

3. The belt is made of imported circular seamless butt belt.

4. Bearings use internationally renowned brand TR bearings.

5. The screw screw, screw and nut are all made of 45# high-quality steel and quenched and processed.

FAQ

| Q | A |

| Are you the trader or manufacturer? | We are the manufacturer with export qualification |

| Do you make oem? | Yes.here can do |

| 5.where are your factory located in? | We are in dongguang town,cangzhou city,hebei,china |

| What is your business process? | Talking about clients requirements, confrim machines, make sales contract,pay for deposit,supplier arrange production,finish producing machines,buyer test machines,buyer pay for the balance payment,supplier delivery machine. |

![]()