Max Cardboard 1200*2530mm Carton Folder Gluer Machine 2.2KW High Potency

-

Highlight

Carton Folder Gluer Machine 2.2KW

,Carton Folder Gluer Machine high potency

,carton folding and gluing machine High Potency

-

Voltage380V

-

ConditionNew

-

Weight5.45kg

-

TypeGluing Machine

-

Automatic GradeAutomatic

-

Dimension(l*w*h)13700 *1600*2200 Mm

-

Packaging TypeCase

-

ApplicationMachinery & Hardware

-

Packaging MaterialWood

-

Driven TypeElectric

-

CertificationCE,ISO

-

Warranty1 Year

-

Power2.2KW

-

NameBox Folder Gluer Machine

-

Place of OriginCHINA

-

Brand NameKSPACK

-

CertificationCE ISO

-

Model NumberKSJ

-

Minimum Order Quantity1SET

-

PriceDollar 5000USD-25000USD

-

Delivery Time5-8weeks

-

Payment TermsL/C, D/A, D/P, T/T

-

Supply Ability1 set 40per days

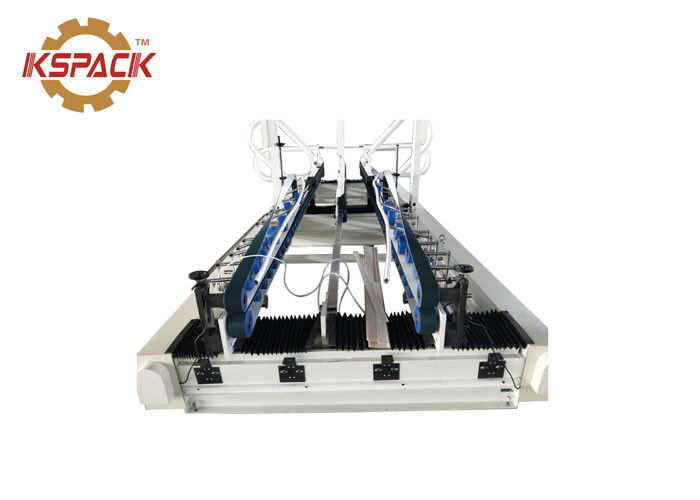

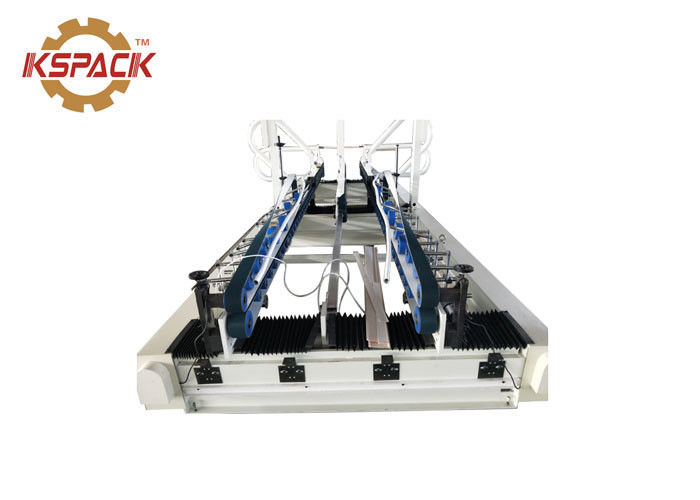

Max Cardboard 1200*2530mm Carton Folder Gluer Machine 2.2KW High Potency

Auto Box Folder Gluer Machine 11.5KW 1200*2530mm Red Machine

|

Model |

2800 |

|

Max cardboard |

1200*2530mm |

|

Min cardboard |

300*700mm |

|

Installation area |

3600*15500mm |

|

Power Required |

11.5KW |

Box Folder Gluer Machine Introduce

AFG Automatic folder gluer machine consist of three sections :

vacuum feeding section , glue and folding section ,counter and stacker sectio n ,

PLC digital speed control ,Remote speed control Touch screen control system for easy and Accurate operation.It can realize Automatic feeding, automatic folding and gluing, automatic counting, and automatic stacking output,Front and rear synchronous dual operation,Average speed is 120 m / min, the maximum speed can reach 160 m / min,With order storage memory function,Efficient energy conservation and environmental protection is our highest pursuit

-

Automatic bending and coating.

-

Applicable carton wide range, different sizes carton adjustment is simple and quick.

-

The machine runs smoothly and reliably, the packaging effect is firm and beautiful. Equipment operation is simple and easy to maintain.

-

With a separate pre-pressure wheel, solve the printing press line bad problem effectively. automatically correct the carton straight angle, effectively correct scissors fork, fish tail and so on.

-

A separate correction system can effectively control the carton scissors.

Box Folder Gluer Machine Product Structure:

Instrument Control:

Easy touch screen opeation imput , whole machine adopt the plc computer programs controller , digital number operater , touch screen input the data , can be change the data, speed no need stop the machine , ,whole machine automatic supply the paper ,auto folder ,auto counter , auto stacker ,feed out , the speed 120m/min ,max speed 160m/min

Paper feed section:

-

cardboard height adjustment structure,Choose high-quality steel , fast adjustment of a variety of box height and cardboard length.

-

Paper suction Belt selection of high-tech materials, tensile layer seamless connecting, gurantee the machine use not have fault

-

Paper feed suction motor, main rotating motor are selected from Taiwan's high-quality, high stability motor.

-

Choose high-grade electromagnetic clutch and electromagnetic brake system, so that the paper can be a single sheet or continuous operation, effective control cardboard waste. of the adjustment.

Glue coat and folder part:

-

motor choose import brand , Stable performance, convenient speed, no noise pollution.

-

Folding part of the use of imported high friction, ultra-wear sp special materials made of seamless connecting conveyor belt, accurate and complete the automatic folding cardboard

-

Glue part choice high-quality stainless steel, even glue coat. save the glue .

-

Folding Department is equipped with double-track correction device, accurate and effective correction of cardboard crease line deviation, so that the entire carton to complete the most accurate folding.

Correction and output part :

Automatic correction and stacking output have automatic counting, piled up neatly, stacking output, according to the customer demand can Set up product box can do how much output , and automatically force calibration the scissors and other non-standard carton forming.

Spear part choose details

-

1.The whole machine uses 380V AC, power 11.5KW, energy saving and high efficiency.

-

2. PLC computer components, frequency conversion components, electrical components are selected from high quality imported components.

-

3. The belt is made of imported circular seamless butt belt.

-

4. Bearings use internationally renowned brand TR bearings.

-

5. The screw screw, screw and nut are all made of 45# high-quality steel and quenched and processed.

|

Spec |

Name |

Qty |

brand |

|

1 |

Touch screen |

1 |

Delta |

|

2 |

PLC |

1 |

Delta |

|

3 |

Requency motor |

2 |

Delta |

|

4 |

Intermediate relay |

3 |

Omron |

|

5 |

Photoelectric switch |

4 |

Ort |

|

6 |

Switching power supply |

9 |

Delta |

|

7 |

Thermal overload relay |

3 |

Chint |

|

8 |

breaker |

2 |

Chint |

|

9 |

Limit switch |

4 |

Chint |

|

10 |

Contactor |

3 |

Siemens |

|

11 |

Button |

11 |

Schneider |

Box Folder Gluer Machine with converyor

1. Equipment Model: HC-ZXK333

Current, power: 380V / 50Hz, 3KW / 5A

2. Countertops high: 800 - 900 mm adjustable

3. Baler speed: ≤ 1.5 seconds / Road

4 machine speed: the maximum speed of 15 boxes / minute (1 meter in length and width of 500 mm packaging packaged together)

5. Pressure: 6kg / cm ²

6. Packing size: the largest size L1250 * W1450 * H450; the smallest size; L400 * W400 * H60

7. Binding force: 0-85kg (adjustable)

8. Strapping form: parallel to 1 ~ 2 ways, the way photoelectric control, manual and so on.

9. Table roller conveyor, when not required bundling can be directly transported

10 strapping requirements: width of 5 (± 0.1) mm, thickness of 0.45-0.8 (± 0.1) mm

11. Warranty: One year warranty, lifetime free home repair, free home service fee (domestic only)

(1) steering mechanism

1. Power: 380V, 50Hz, 800W;

2. Stents using Q235A steel;

3. Drum with stainless steel;

4. Roller diameter: φ50mm, wall thickness: 2.5mm;

5. Each roller center distance 80mm; line width 1400MM

6. Conveying speed: 50m / min;

7. Electrical configuration: China "MEIWA";

8. Performance: with a dedicated assembly line, the object delivered to the cross steering device, the top of the rotation 90 degrees, the final decline, continue to transport

(2) delivery all around the body

1. Power: 380V, 50Hz, 1200W;

2. Bracket, steel beam: Q235-A surface spray

3. Roller: stainless steel tube

4. Roller diameter: φ50mm, wall thickness: 2.5mm

5 roller center distance 80mm, line width 1400MM

6 Conveyor speed: 50 m / min

7 electrical configuration: China "MEIWA" motor

(3) automatic strapping machine

1. Banding speed **: ≤ 1.5 seconds / channel

2. Bonding method: hot melt method

3. Bonding: bottom bonding, bonding surface ≥ 90%, bonding width ≥ 20%, bonding position deviation ≤ 2mm

4. Strapping tightness: 0-45kg

Power: 600W, 10 A

6. Power: 1P, 220V, 50Hz (standard reference machine nameplate)

7. Working noise: ≤ 75DB

8. Adjustable options: frame size, bandwidth

![]()