High Precision Cardboard Laminating Machine Automatic Flute Laminator 6.4kw

-

Highlight

High Precision Cardboard Laminating Machine

,Automatic Flute Laminator 6.4kw

,Cardboard Laminating Machine 6.4kw

-

Automatic GradeAutomatic,Semi-Automatic,manual

-

Weight5T,About 3T,450Kg,3 Ton,230kg

-

Driven TypeElectric,Pneumatic,Hydraulic,Mechanical

-

TypeLaminating Machine,high Speed Semi-automatic Flute Laminating Machine,laminating Machine And Flip Flop Machine

-

ApplicationMachinery & Hardware

-

Voltage380V

-

Packaging MaterialWood,Paper,Plastic,Metal,Glass

-

Packaging TypeCartons,Case,Film,Bags,Cans

-

Power12kw,6kw,7 KW,6.4kw,500W

-

Warranty1 Year,12 Months,one Year,3 Years,2 Years

-

ColorCustomer's Request,Picture Color Can Also Make According To Your Requirement

-

NameFlute Laminating Machine,flute Corrugated Board Paper Laminating Machine / Laminator Machine

-

FunctionPressing,For Cutting Cardboard

-

Place of OriginCHINA

-

Brand NameKingSun

-

CertificationCE ISO

-

Model NumberKSJ

-

Minimum Order Quantity1SET

-

PriceDollar 5000USD-25000USD

-

Delivery Time5-8weeks

-

Payment TermsL/C, D/A, D/P, T/T

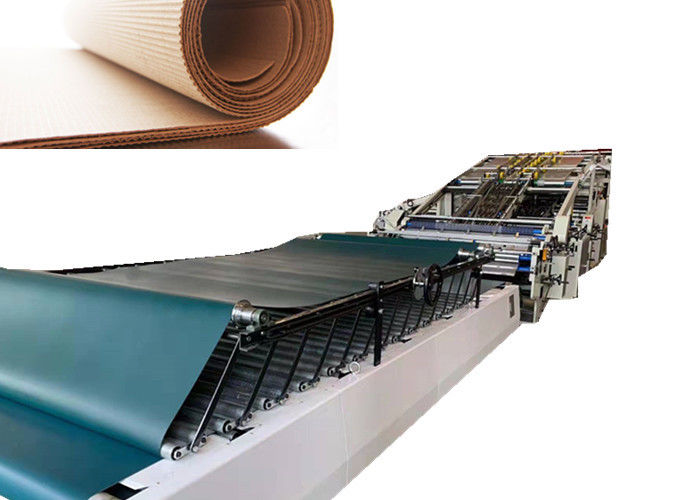

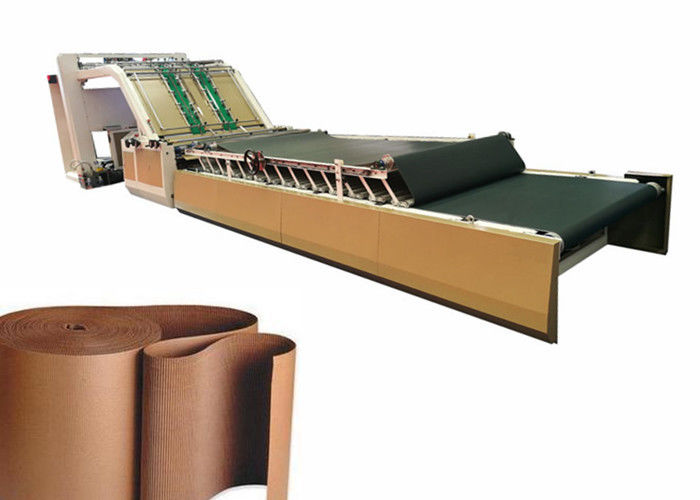

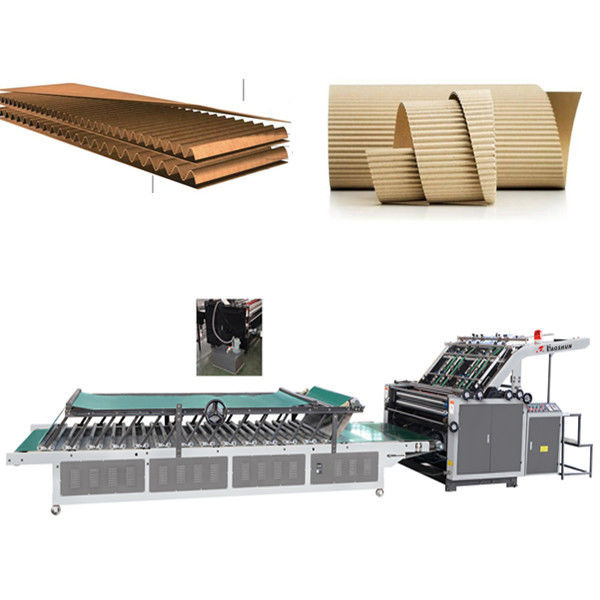

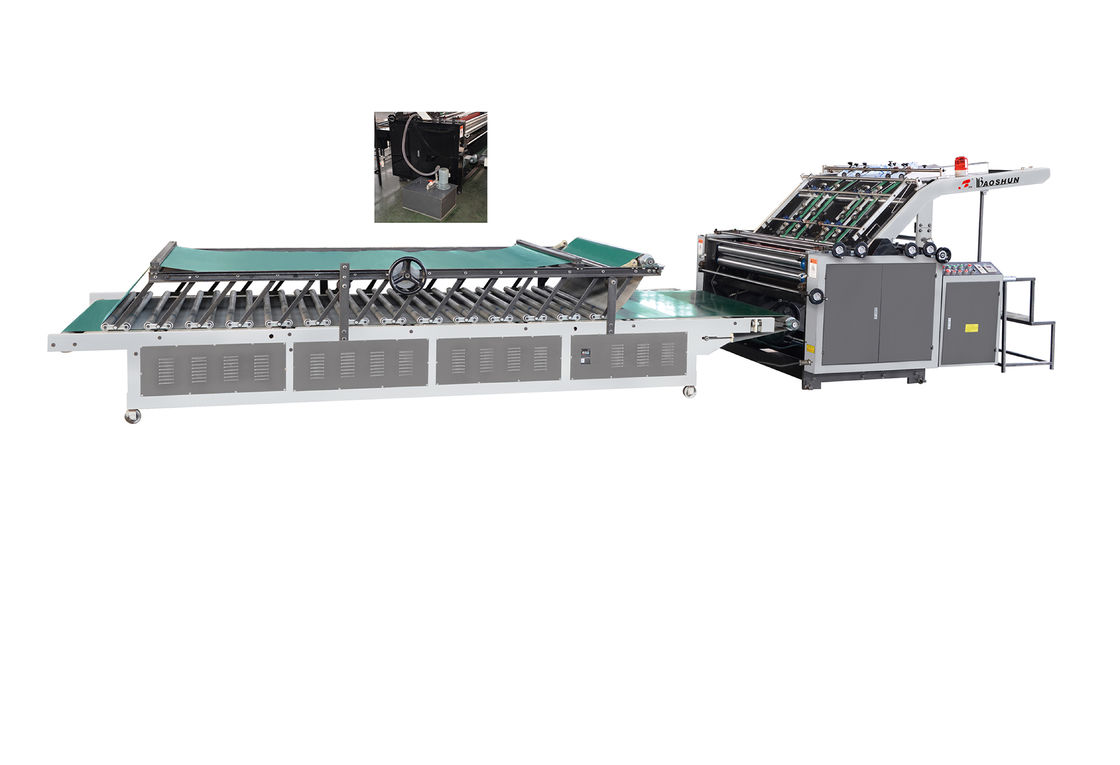

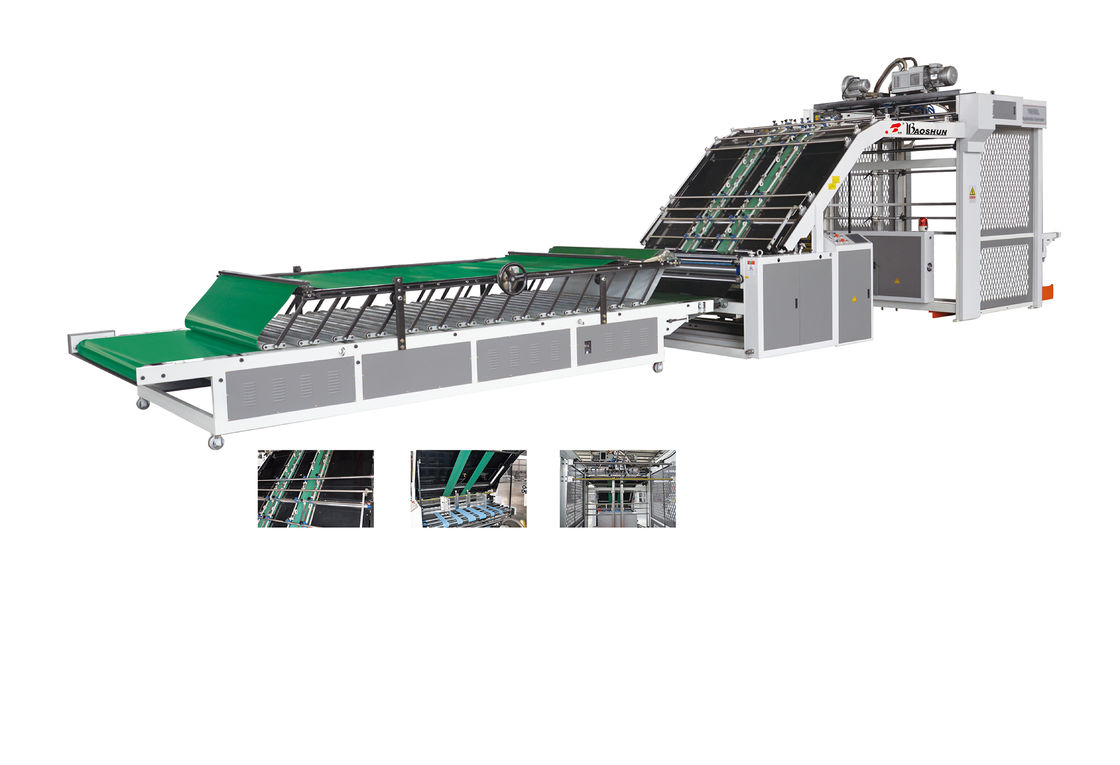

High Precision Cardboard Laminating Machine Automatic Flute Laminator 6.4kw

High Precision Lamination Machine

Machine Description

Suction floating-feed paper, running balance is accurate. Photoelectric control to avoid single - sheet walking. The machine adopts forward push position: the error range is within 1.0mm, and the fitting error range of corrugated paper is within 1.5mm.The 20 thick parts of the wall panels are 40 thickness.

![]()

![]()

![]()

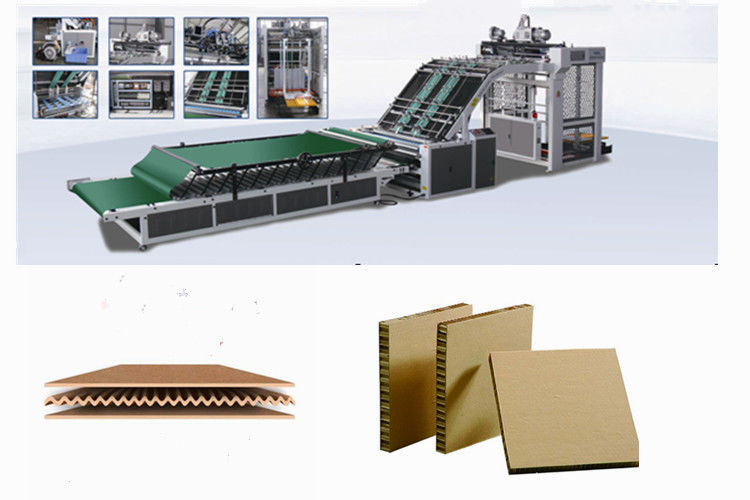

Machine Function

The machine is easy to clean by lifting bridge board. Intermittent water cycle cleaning system, easy to clean.

Elastic front position, the backing paper does not lead, and the backing paper can be adjusted before and after laminating.

Suitable for over 350 grams of low card and paperboard, paperboard and A/B/C/E/F and double corrugated board and corrugated and corrugated.

Intelligent control of flattening, up to power saving and control paper folding distance.

Adopt high precision glue blocking device to save glue.

![]()

![]()

|

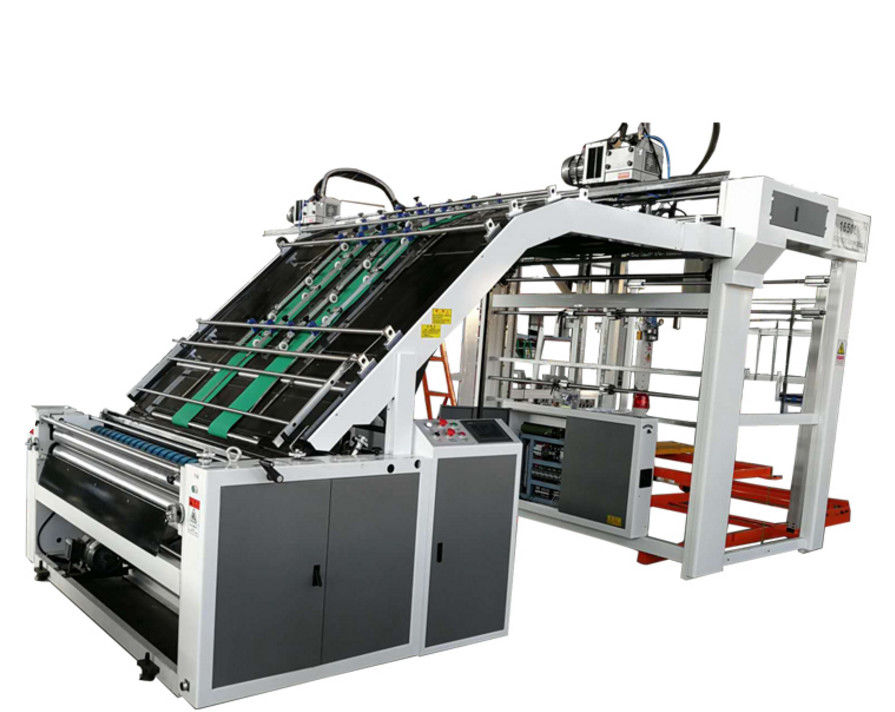

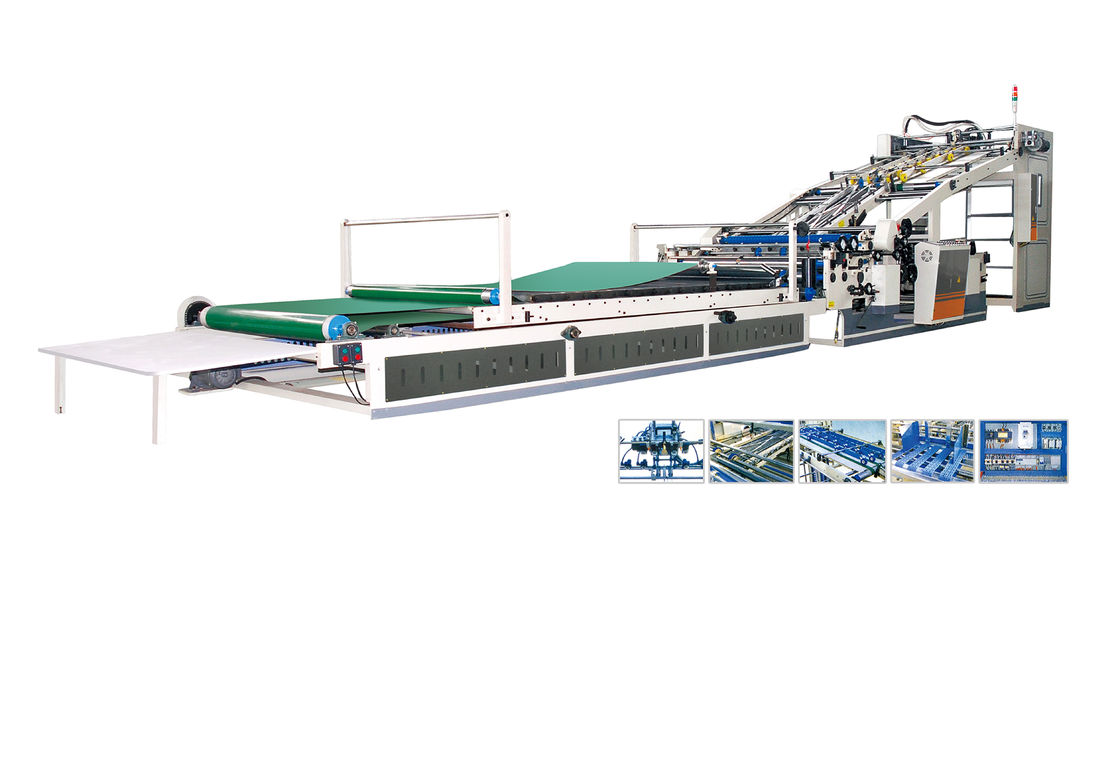

Item |

Description |

|

Surface Paper Feeding Part |

The Feeding device made in Taiwan ensures that the feeding of surface paper is smooth and accurate. |

|

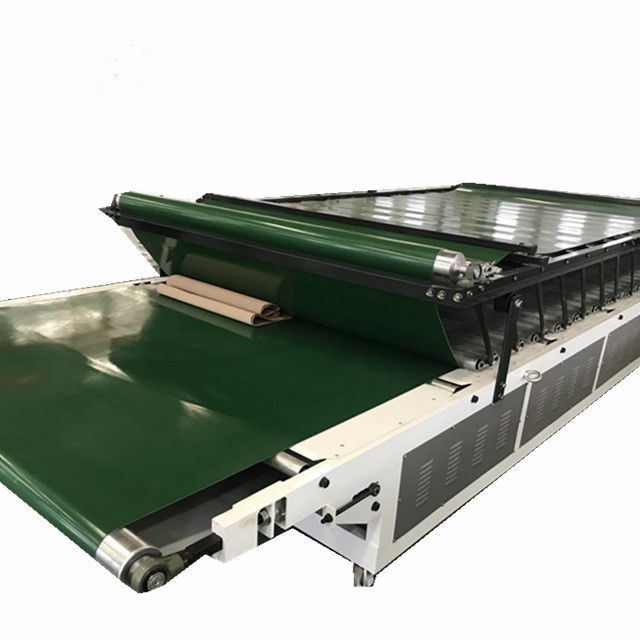

Surface Paper Conveying Part |

Unique central gear made of wear-resistant PU rubber cooperating with conveying belt ensures stability and smoothness of conveying, which is adaptive for different sheets of different thickness without any abrasion for the printing surface. |

|

Alignment System of Surface Paper |

Synchronous sheet pusher particularly designed ensures that the surface paper and bottom paper enter the pasting part at the same time. It can be fine adjusted during the course of working. |

|

Bottom Paper Feeding Part |

Imported suction feeding device with punching belts ensures stable feeding at high speed. It is suitable for cardboard heavier than 300g/m2, corruggated boards of A,B,C,D,E,F,N and three, five or seven layers. |

|

Bottom Paper Conveying Part |

Synchronous sheet pusher particularly designed ensures the stable and accurate conveying of cardboards heavier than 300g/m2, and corrugated boards of A,B,C,D,E,F,N and three, five or seven layers. |

|

Driving System |

Imported wear-resistance timing belt, belt wheels cooperating with sheet pusher, adjustment system and alignment mechanism ensures a paste tolerance of ±1.5mm and reduction of torn sheet. |

|

Electrical Control Part |

All the electrical power adopted the worl drenowned brands, steady and dureable, frequency speed govering, lower noise and energy conservation. |

Our Company

We are a professional supplier of corrugated machinery,including automatic high speed flexo printer slotter die cutters,corrugated board production lines,Rotary die cutters, carton staplers and two ply corrugated board production lines.Along with our development,we have set up our own factories. We are now enlarging our product area to testing equipment and other kinds of packaging machinery.

FAQ

1.Q:Are you the trader or manufacturer?

A:we are the manufacturer with export qualification

2.Q:Do you make OEM?A:Yes.herecando

3.Q:Where are your factory located in?

A:we are in Dongguang town,Cangzhou city,Hebei,China

4.Q:What is your business process?

A: Talking about clients requirements, confrim machines, make sales contract,pay for deposit,supplier arrange production,finish producing machines,buyer test machines,buyer pay for the balance payment,supplier delivery machine