-

Highlight

5 Ply Flute Laminator Multilayers

,Automatic Flute Laminator Machine Multilayers

,Automatic Flute Laminator Machine 6000pcs/h

-

Automatic GradeAutomatic,Semi-Automatic,manual

-

Weight5T,About 3T,450Kg,3 Ton,230kg

-

Driven TypeElectric

-

After-sales Service ProvidedEngineers Available To Service Machinery Overseas

-

TypeLaminating Machine,high Speed Semi-automatic Flute Laminating Machine,laminating Machine And Flip Flop Machine

-

ApplicationMachinery & Hardware,Food,Commodity,Medical,Beverage

-

Voltage380V,380V/50HZ,220/380V,380V/220V,220v

-

ConditionNew

-

NameFlute Laminator Machine

-

Place of OriginCHINA

-

Brand NameKingsun

-

CertificationCE ISO

-

Model NumberKSJ

-

Minimum Order Quantity1SET

-

PriceNegotiate

-

Delivery Time5-8weeks

-

Payment TermsL/C, D/A, D/P, T/T

-

Supply Ability1 set 40per days

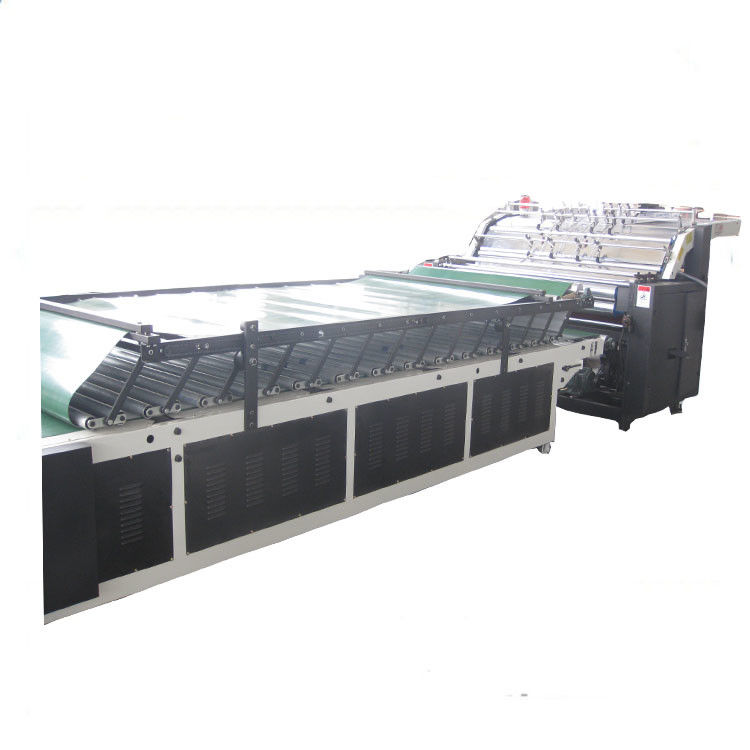

3 4 5 Ply high speed auto Flute Laminator Machine With 6000PCS/H

3 4 5 Ply High Speed Auto Flute Laminator Machine With 6000PCS/H

Flute Laminator Machine Introduction:

Multifunctional laminating machine, can produce 5/4/3 (2+2+1=5 /4+1=5/2+2=4/2+1=3) layers corrugated cardboard.

KS-F series fully automatic multi-layer flute laminator is consists of automatic face paper lifting section, face paper conveying section, double bottom paper synchronized or asynchronized conveying section, double bottom paper position section, cyclic gluing section,pressing section, delivering section and automatic collecting section. It suits to laminate the printed paper to the corrugated cardboard or cardboard which is thicker than 350 gsm, with features of high precision and high speed. It is the ideal laminating machine for all kinds of packaging company domestic and overseas.

Flute Laminator Machine Specification:

|

Model |

KS-1300F |

KS-1450F |

KS-1600F |

|

Max paper size |

1300x1200mm |

1450x1200mm |

1600x1200mm |

|

Min paper size |

600x600mm |

||

|

Face paper thickness |

150-600gsm |

||

|

Bottom paper |

A/B/C/E/F/G 2ply flute |

||

|

Precision |

1.5 mm |

||

|

Max Speed |

6000pcs/h |

||

|

Height of face paper pile |

1600mm |

||

|

Face paper table capacity |

1500kg |

||

|

Height of bottom 2ply pile |

400mm |

||

|

Total power |

20kw |

||

|

Dimension |

15x2.2x2.6m |

15x2.4x2.6m |

15x2.5x2.6m |

|

Machine weight |

5000kg |

5500kg |

6000kg |

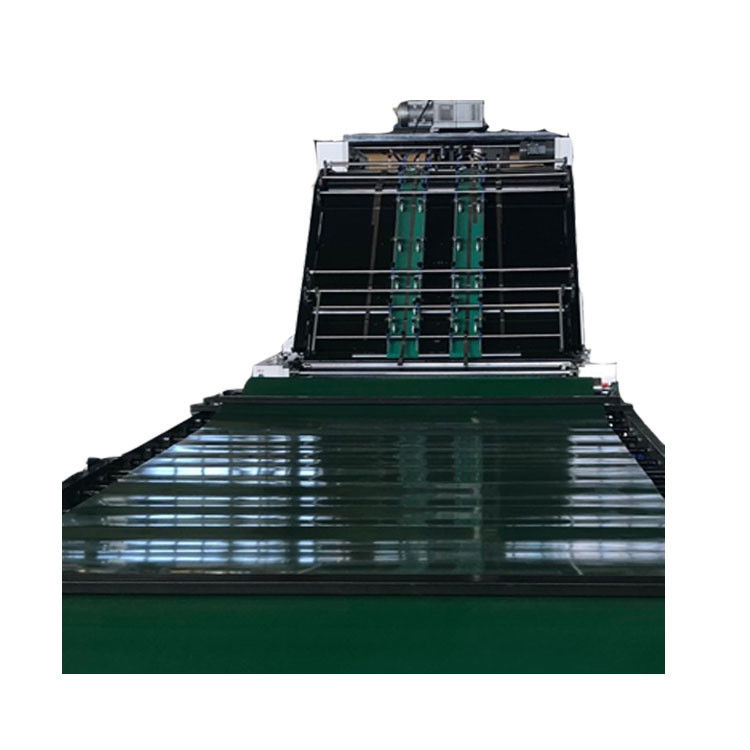

Flute Laminator Machine Machine structure:

1. Face paper conveying section adopts advanced four sucking and four delivering feeder, with the help of high pressure vacuum pump it can feed the face paper 180-600gsm efficiently. Position displaying hand wheel on the face paper pile loading section makes the loading action more accurate and more convenient for the bottom paper loading at the same time. Limited switch fixed on face paper loading section makes the moving up action more accurate.

2. Conveying belt, pressing roller and automatic chasing lay all do help to the face paper delivery. Pressing roller adopts the specialized roller which is used on print machine, it can delivery both thick and thin paper effectively. Anti-curl structure helps to delivery face paper at the same time.

3. Both bottom paper feeding section adopt vacuum sucking belt with high strength and high friction allowing the non-stop feeding. Rotating paper supporter equipped on this section makes it possible to feed the long sheet.

4. Knurled roller on the bottom feeding part makes sure the stable running when the machine in a high speed.

5. Chasinglay and high-speed axial flow fan differential positioning system is applied on the bottom paper feeding part.

You can adjust the front and back position without stopping the machine. Synchronous slot design can control the bottom paper feeding in a minimum range; Chasing lay can make sure a good bottom sheet feeding when the machine is running at a high speed.

![]()