-

Highlight

480volt Semi Auto Flute Laminator

,480volt Corrugated Laminating Machine

,Corrugated Laminating Machine 6000pcs/H

-

ConditionNew

-

Voltage220/380/480volt

-

Warranty3 Years

-

Product Type3-layer Corrugated Board Producing Machine

-

TypeHigh Speed Semi-automatic Flute Laminating Machine

-

NameFlute Laminator Machine

-

Place of OriginCHINA

-

Brand NameKingsun

-

CertificationCE ISO

-

Model NumberKSJ

-

Minimum Order Quantity1SET

-

PriceNegotiate

-

Delivery Time5-8 work days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Supply Ability1 set per 30 days

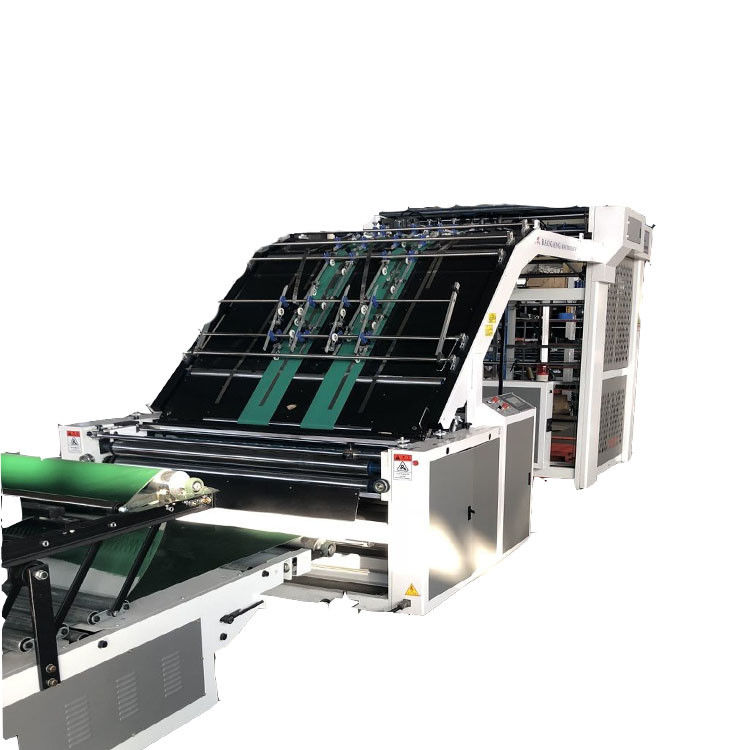

220 / 380 / 480 Volt Semi Auto Flute Laminator Machine 6000pcs/H

Low Noise TMQ Model Flute Laminator High Speed Semi Auto Flute Corrugated Laminating Machine

Corrugated cardboard laminating machine is a kind of equipment that can laminate different materials on the surface of corrugated cardboard, such as paper, film, cloth, leather, etc. It can improve the appearance and quality of corrugated cardboard, and expand its application range.

The working principle of corrugated cardboard laminating machine is to use glue to bond the surface material and the corrugated cardboard together. The glue can be water-based or solvent-based, depending on the type of surface material and the requirements of the final product. The glue is applied on the surface material by a roller or a spray nozzle, and then the surface material is pressed onto the corrugated cardboard by another roller or a press plate. The laminated product is then dried by a hot air oven or a UV lamp.

The main components of corrugated cardboard laminating machine are: feeding unit, gluing unit, laminating unit, drying unit and cutting unit. The feeding unit is used to feed the surface material and the corrugated cardboard into the machine. The gluing unit is used to apply glue on the surface material. The laminating unit is used to press the surface material and the corrugated cardboard together. The drying unit is used to dry the laminated product. The cutting unit is used to cut the laminated product into desired sizes and shapes.

The advantages of corrugated cardboard laminating machine are: it can laminate various materials on the corrugated cardboard, such as paper, film, cloth, leather, etc., to enhance its appearance and quality; it can produce different kinds of products with different functions and effects, such as waterproof, anti-static, anti-corrosion, etc.; it can save raw materials and reduce production costs by using recycled or waste materials as surface materials; it can improve production efficiency and reduce labor intensity by using automatic or semi-automatic control system.

|

Model |

KS-1300F |

KS-1450F |

KS-1600F |

|

Max paper size |

1300x1200mm |

1450x1200mm |

1600x1200mm |

|

Min paper size |

600x600mm |

600x600mm |

600x600mm |

|

Face paper thickness |

150-600gsm |

150-600gsm |

150-600gsm |

|

Bottom paper |

A/B/C/E/F/G 2ply flute |

A/B/C/E/F/G 2ply flute |

A/B/C/E/F/G 2ply flute |

|

Precision |

1.5mm |

1.5mm |

1.5mm |

|

Max Speed |

6000pcs/h |

6000pcs/h |

6000pcs/h |

|

Height of face paper pile |

1600mm |

1600mm |

1600mm |

|

Face paper table capacity |

1500kg |

1500kg |

1500kg |

|

Height of bottom 2ply pile |

400mm |

400mm |

400mm |

|

Total power |

20kw |

20kw |

20kw |

|

Dimension |

15x2.2x2.6m |

15x2.4x2.6m |

15x2.5x2.6m |

|

Machine weight |

5000kg |

5500kg |

6000kg |

Our Company

We are a professional supplier of corrugated machinery,including automatic high speed flexo printer slotter die cutters,corrugated board production lines,Rotary die cutters, carton staplers and two ply corrugated board production lines.Along with our development,we have set up our own factories. We are now enlarging our product area to testing equipment and other kinds of packaging machinery.

FAQ

|

Q |

A |

|

Are you the trader or manufacturer? |

We are the manufacturer with export qualification |

|

Do you make oem? |

Yes.here can do |

|

5.where are your factory located in? |

We are in dongguang town,cangzhou city,hebei,china |

|

What is your business process? |

Talking about clients requirements, confrim machines, make sales contract,pay for deposit,supplier arrange production,finish producing machines,buyer test machines,buyer pay for the balance payment,supplier delivery machine. |

After Sales Service

Free Shipping Replacement Spare You just need to pay the freight

One To One Video Teaching We Provide Operation & Maintenance cd

-11 years experience

-Export to more than 150 countries

-Professional international sales more than 30 persons

-Professional sale team

technical team and after-sales service team

Our KSPACK Group :

Hebei Jinguang Packing Machine Co.,Ltd

Cangzhou Kingsun IMP and EXP Co.,Ltd

Dongguang Qunbang Carton Machinery Co.,Ltd

![]()