-

Highlight

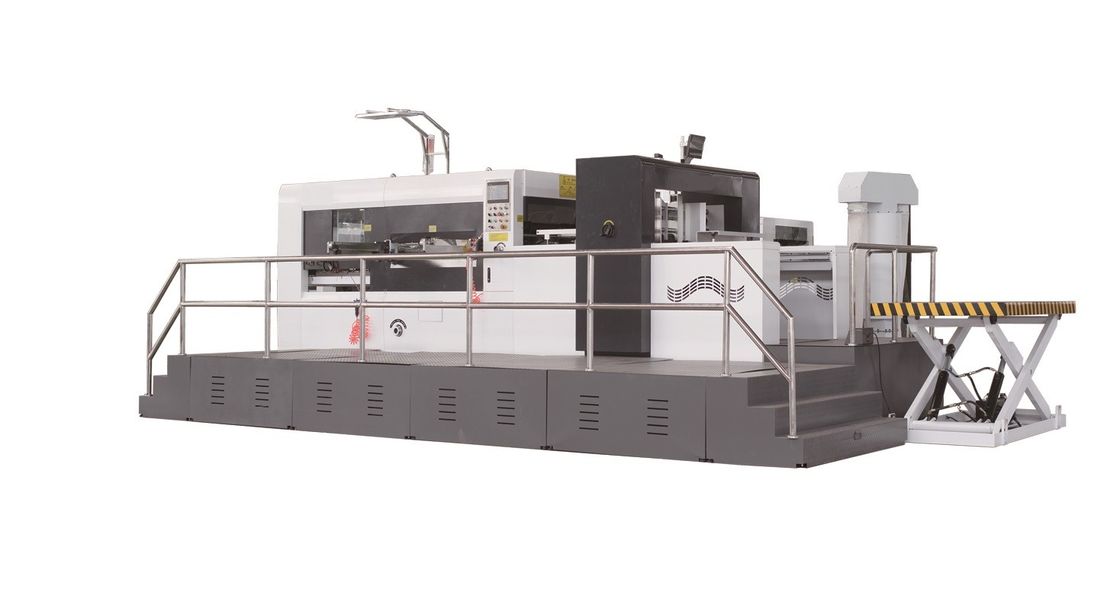

4600pcs/h cardboard box die cutting machine

,1100mm cardboard box die cutting machine

-

NameAutomatic Plate Diecutter Machine

-

FeederAutoamtic Lead Edge Feeder

-

Diecutter ModelFlat Diecutter ,die Punch Machine

-

Corrugated Sheet1-8mm

-

The Machine Size1100 .1200 .1500mm Choose

-

The Pressure Of The Machine380n/cm2

-

Speed4600-6000pcs Per Hour

-

Place of Originchina

-

Brand Namekspack

-

Model Number1100 1200 1500

-

Minimum Order Quantity1set

-

Price100000-150000usd

-

Packaging DetailsFULL CONTAINER ,

-

Delivery Time30DAYS

-

Payment TermsL/C, T/T

-

Supply Ability5sets per month

1100mm 4600pcs/H Cardboard Box Die Cutting Machine

ead edge or feidar automatic plate corrugated and cardboard box case diecutter machine

Feeding and Collecting Part

- Equipped with lead edge feeder ,it can prevent the cardboard damage by the black wheels.

- Independent servo actuator can assure the cardboard send to right position and avoid crash on the paper

- The big power suction fan and the adjusted wind system work for 1-9mm corrugated box

Diecutting part and Delivery system

- Diecutting chase fixed accurately by pneumatic lock system

- Diecutting plate is putted in and out by air floating device

- Electric clutch system of main chain can assure the chain steady when it is stopped at high speed

- Main chain and assist chain is lubricated periodically controlled by PLC

- Protection window of diecutting can hold the main body clean

- Lightweight and durable aluminum alloy gripper bars with chain of Renold UK or Germany Iwis ensure accura

stripper part

- Double action movement structure with upper and lower stripping frame facilitates die change

- Male/female diecutter model are available for different carton

- Match with the centerline registration system in diecutting area, there is a same system in the stripping section.Accurate positions can increase production efficiency

| Item | Parameters |

| Model | MY-1300 |

| Die cutting type | Pressed flat die cutting(Lower side is movable while upper side is unmovable) |

| Max paper transmitting size | 1320*980mm |

| Min paper transmitting size | 350*450mm |

| Max die cutting size | 1300*960mm |

| Max stripping size | 1300*940mm |

| Min gripper size | 8mm |

| Max die cutting pressure | 350N/cm² |

| Paper processed | Corrugated board 1-10mm |

| Max die cutting speed | 4600 sheets/h |

| Main motor power | 11 kw |

| Total power | ~24 kw |

| Total weight | ~19.5 T |