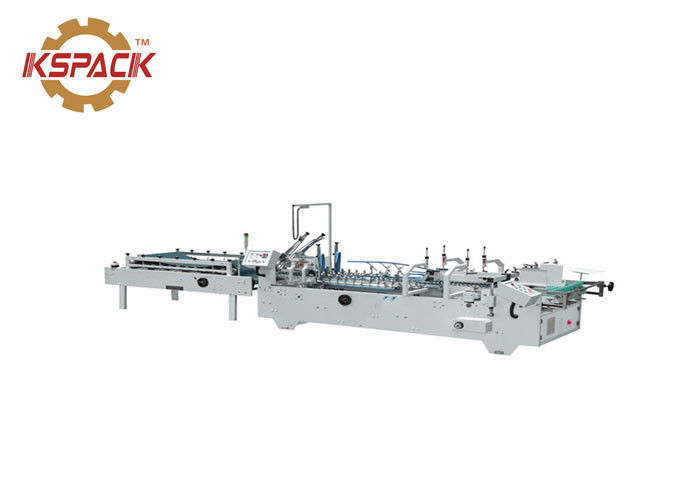

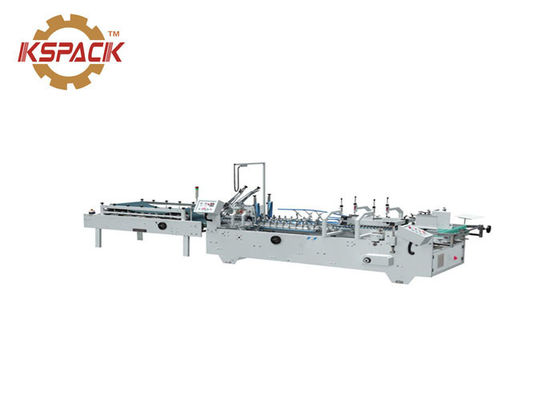

Medicine Box And Cosmetics Box Automatic Gluing Machine , Automatic Folding Machine

-

Highlight

automatic folding machine

,box folder gluer machine

-

Machine NameMedicine Box And Cosmetics Box Automatic Gluing Machine , Automatic Folding Machine

-

ApplicationMake Box Forming Machine

-

FeatureFast Speed Reasonable Structure

-

Weight2200kg

-

ColorWhiter

-

Service1 Year Warranty

-

Place of OriginChina Hebei

-

Brand NameKingsun

-

CertificationCE

-

Model NumberKSHG

-

Minimum Order Quantity1 Set

-

PriceNegotiable

-

Packaging DetailsWrapped in plastic film and placed in wooden box

-

Delivery Time5-8 work days

-

Payment TermsL/C, T/T, Western Union

-

Supply Ability2 Set 40 per days

Medicine Box And Cosmetics Box Automatic Gluing Machine , Automatic Folding Machine

Medicine Box And Cosmetics Box Automatic Gluing Machine , Automatic Folding Machine

(4) Bottom edging part:

The bottom edging process is that the paper box moves on the conveying belt, through the bottom edging part and glue from the gluing disc bottom, 4 box hooks and 2 bottom edging blocks to finish the bottom edging. Its process is as the following diagram.

(5) Gluing part

In the course of pasting box, the size of gluing amount and gluing position are key point. The gluing device should coat the glue liquid on the adhesive place of paper board evenly, finally make the paper box stick firmly. When adjusting, first as the paper sheet width and gluing position and then adjust the glue box to be stuck firmly. The glue box position can use the wrench to twist the screw on the glue box fixed plate to drive the glue box removal. The glue amount can be adjusted through the adjustable screw front and behind. The function of the paper pressed wheel is to prevent the paper sheets from bending upwards while gluing, paper sheets can not be touched with the gluing wheel and the glue can not coat on the paper sheets evenly. Rotate the adjustable screw to properly adjust the position of paper pressed wheel and the height, so that the glue liquid can be guaranteed to coat on the adhesive place of paper sheets.

(6) Fold part:

A. The loose or tight degrees of up and down, left and right of four fold belts should be identical. Two upper adjustable handles can adjust the two upper belts and two lower adjustable handles can adjust the two lower belts (they all can be adjusted separately).

B. Both side removal rows can be adjusted with the handwheel according to the paper box size. Adjust the both sides belt widths should be wider 1-2 mm than that of the folded box edge folded trace. The both widths of folded knife row should be less 1-2 mm than that of the paper box folded trace. The height between the folded knife and belt should be wider and loose a little that the thickness of a piece of paper. The upper and lower, front and behind of the folded knife rows all have the adjustment part, which can be fixed on the removal rows, thus it’s unnecessary to adjust the knife rows to the paper boxes which thicknesses are not differ too much.

6. Paste box size

SHH-800AG

| Type of boxex | Amax | Amin | Bmax | Bmin | Cmin | Dmin | Fmin |

| No-edged bottom box | 700mm | 700mm | 620mm | 110mm | 8mm | 70mm | 51mm |

| Edges bottom box | 700mm | 160mm | 570mm | 180mm | 9mm | 90mm | 85mm |

SHH-1200AG

| Type of boxex | Amax | Amin | Bmax | Bmin | Cmin | Dmin | Fmin |

| No-edged bottom box | 700mm | 110mm | 840mm | 110mm | 8mm | 70mm | 51mm |

| Edges bottom box | 700mm | 160mm | 790mm | 180mm | 9mm | 90mm | 85mm |