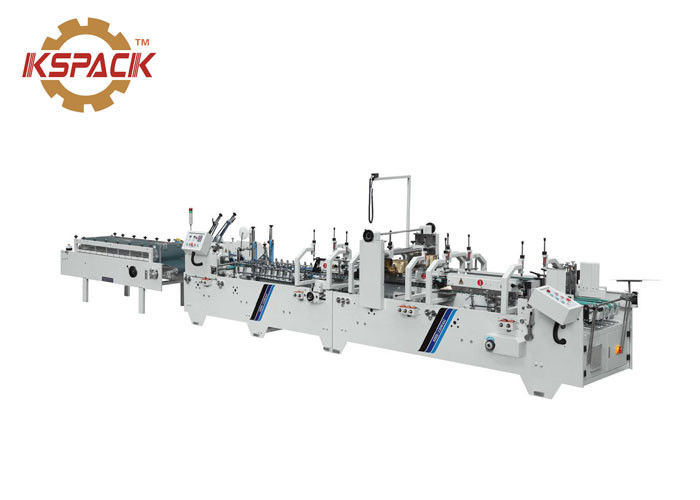

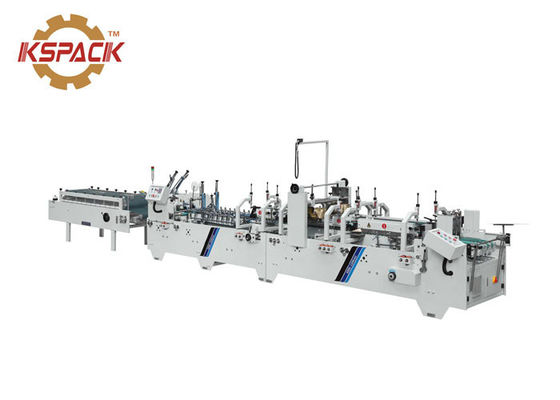

Automatic Box Carton Folding Machine , Carton Gluing Machine For Gift Boxes

-

Highlight

carton folder gluer machine

,box folder gluer machine

-

Machine NameAutomatic Box Carton Folding Machine , Carton Gluing Machine For Gift Boxes

-

UsageSmall Box Forming Machine

-

Weight2200kg

-

AutomatizationAutomatic

-

Size9300x1650mm

-

TypeKSHG900

-

Place of OriginChina Hebei

-

Brand NameKingsun

-

CertificationCE

-

Model NumberKSHG

-

Minimum Order Quantity1 Set

-

PriceNegotiable

-

Packaging DetailsWrapped in plastic film and placed in wooden box

-

Delivery Time5-8 work days

-

Payment TermsL/C, T/T, Western Union

-

Supply Ability2 Set 40 per days

Automatic Box Carton Folding Machine , Carton Gluing Machine For Gift Boxes

Automatic Box Carton Folding Machine , Carton Gluing Machine For Gift Boxes

Adjust the fold box width according to the width size of fold box paper sheet. Only need to rotate the handwheel according to the width shown as Fig. IV to make the screw rod rotate, because the front and behind screw rods are connected with the chain, the two main plates will move in parallel at the same time while rotating the handwheel. After the two main plates reach the desired fold box width, the start the machine to have a trial and carry out the detail adjustment to the various fold box wheel, conveying belt etc. Finally reach the purpose that the paper sheets can pass successfully and the fold box position can be correct and have an enough adhesive force.

(3) Pre-fold part:

For the convenience to open the straight line box, the two pressed trace parts without folded need to pre-fold. Regarding the box needed to pre-fold, mount and adjust the pre-fold properly. The box outputs from the automatic feeding device (paper feeding part) and then enters the pre-fold device, In the pre-folding part, the first fold and the third fold can be exchanged by 180 degree and 90 degree. The second fold and the fourth fold can be molded in 180 degree, the special design is also available. The pre-folded paper box opens very easily on automatic packer,especially the medicine box

(4) Bottom edging part:

The bottom edging process is that the paper box moves on the conveying belt, through the bottom edging part and glue from the gluing disc bottom, 4 box hooks and 2 bottom edging blocks to finish the bottom edging. Its process is as the following diagram.

(5) Gluing part

In the course of pasting box, the size of gluing amount and gluing position are key point. The gluing device should coat the glue liquid on the adhesive place of paper board evenly, finally make the paper box stick firmly. When adjusting, first as the paper sheet width and gluing position and then adjust the glue box to be stuck firmly. The glue box position can use the wrench to twist the screw on the glue box fixed plate to drive the glue box removal. The glue amount can be adjusted through the adjustable screw front and behind. The function of the paper pressed wheel is to prevent the paper sheets from bending upwards while gluing, paper sheets can not be touched with the gluing wheel and the glue can not coat on the paper sheets evenly. Rotate the adjustable screw to properly adjust the position of paper pressed wheel and the height, so that the glue liquid can be guaranteed to coat on the adhesive place of paper sheets.

6. Paste box size

SHH-800AG

| Type of boxex | Amax | Amin | Bmax | Bmin | Cmin | Dmin | Fmin |

| No-edged bottom box | 700mm | 700mm | 620mm | 110mm | 8mm | 70mm | 51mm |

| Edges bottom box | 700mm | 160mm | 570mm | 180mm | 9mm | 90mm | 85mm |

SHH-1200AG

| Type of boxex | Amax | Amin | Bmax | Bmin | Cmin | Dmin | Fmin |

| No-edged bottom box | 700mm | 110mm | 840mm | 110mm | 8mm | 70mm | 51mm |

| Edges bottom box | 700mm | 160mm | 790mm | 180mm | 9mm | 90mm | 85mm |