-

Highlight

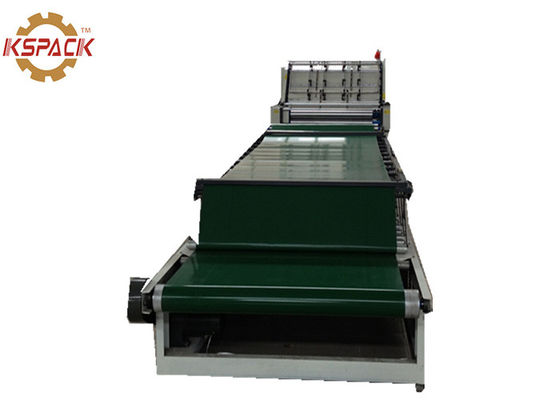

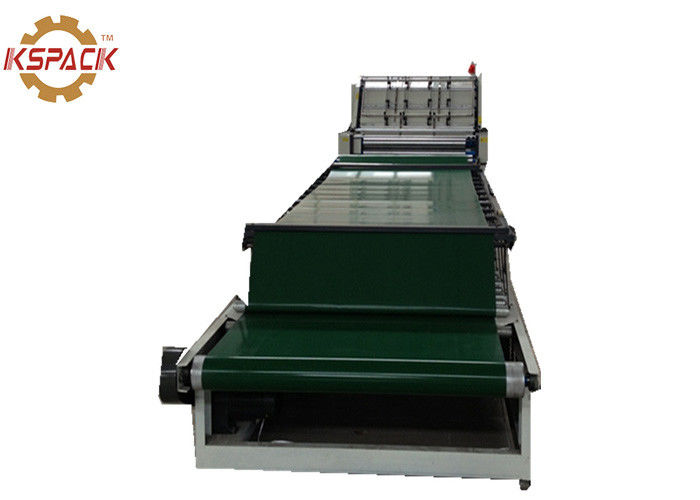

auto feeding flute laminator

,low noise flute laminator

,low noise automatic flute laminator

-

NamePaper Lamination Machine

-

Min Laminator Size360mm*360mm

-

Machine Size8.8m*1.95m*1.5m

-

CertificateCE ISO

-

StaffMore Than 100

-

Speed60-80pcs/min

-

Place of OriginHebei Province, China

-

Brand Namekspack

-

CertificationCE ISO

-

Model NumberTMB

-

Minimum Order Quantity1

-

PriceNegotiable

-

Packaging Detailsin skin , in carton , in container

-

Delivery Time40-60 days

-

Payment TermsL/C, T/T, Western Union, MoneyGram

-

Supply Ability10 set per month

80pcs/Min Auto Feeding A Flute Laminator Low Noise

Corrugated cheap laminating machine , lamination machine manufacturer

The laminating machine is also called the laminating machine or the laminating machine. It is used for the bonding of pre-printed color printing paper and corrugated board. It is an important supporting equipment for the production of pre-printed carton, and the production efficiency and quality of corrugated board processing. Has a certain impact. With the continuous development of the social economy, the application of pre-printed cartons is more and more extensive, the structure of the laminating machine is becoming more diversified and automated, and the manufacturing technology and performance are becoming more mature and advanced. Due to the different structure and performance of the laminating machine, the effect of the corrugated board and the paper sheet is also very different. Therefore, the correct purchase and use of the laminating machine is an important part of improving the production efficiency and quality of the carton.

Features

1.The machine auto feeding corrugated board bottom paper

2.,manual feeding above paper ,( there is high table model ,the top board can pile 1.5meter ,can according the paper feed height adjust the height automatic)

3.above paper can adjust front and behind,never go ahead ,match with the adjust the speed.

.

4.This used to paste the color-printing surface paper together with the bottom paper (cardboard or corrugated sheet) accurately Suitable for lamination of corrugated cardboard A/B/C/D/E/F flute board to paperboard 175-700g , and paperboard175g-700g to grey board .

5.Automatic feeding of bottom sheet and normal front feeding of top sheet With flexible front gauge positioning to control the laminating precision. Stepless timing, novelty and beauty,easy to clean ,easy operation and high laminating precision.

6.New equipment for producing the high quality cardboard, makes the cardboard more striking, nice and high intensity.

7.Used widely for packing food, wine bottle, electric appliance and light industry products.

8. The machine adopt the plc control system , electrical system run steady,and automatic show the error .

| Model | TM1300Q | TM1450Q | TM1600Q |

| Max laminator size | 1300mm×1100mm | 1450mm×1100mm | 1600mm×1100mm |

| Min laminator size | 350mm×350mm | 350mm×350mm | 350mm×350mm |

| Speed | 0-60m/min | 0-60m/min | 0-60m/min |

| Powere | 8.5kw | 9.5kw | 9.5kw |

| Machine size | 8.8m×2.2m×1.5m | 8.8m×2.35m×1.5m | 8.8X2.5X1.5 |

| Weight | 3.2 | 3.5 | 3.7T |

1.The machine auto feeding corrugated board

2.,manual feeding above paper ,

3.above paper can adjust front and behind,never go ahead ,match with the adjust the speed.

.

4.machine is used to paste the color-printing surface paper together with the bottom paper (cardboard or corrugated sheet) accurately Suitable for lamination of corrugated cardboard(A/B/C/D/E/F) to paperboard

(350grams) ,and paperboard 175-500grmas to grey board above 350g

5.Automatic feeding of bottom sheet and normal front feeding of top sheet With flexible front gauge positioning to control the laminating precision. Stepless timing, novelty and beauty,easy to clean ,easy operation and high laminating precision.

6.New equipment for producing the high quality cardboard, makes the cardboard more striking, nice and high intensity.

7.Used widely for packing food, wine bottle, electric appliance and light industry products.

![]()