Full Automatic Die Cutting And Creasing Machine Cardboard Cutting

-

Highlight

paper die cutting machine

,cardboard die cutting machine

-

FeaturesCarton Box Making

-

Cutting MaterialsCorrugated Paper , Cardboard

-

Warranty1 Year

-

UsageDie Cutting The Paperboard

-

ApplicationBox Making

-

Max.cutting Width1100X820mm

-

Place of OriginChina

-

Brand NameKSPACK

-

CertificationCE/ ISO 9001

-

Model NumberML

-

Minimum Order Quantity1 set

-

PriceNegotiable

-

Packaging DetailsWooden case

-

Payment TermsL/C, D/A, D/P, T/T, Western Union

-

Supply Ability20 set per month

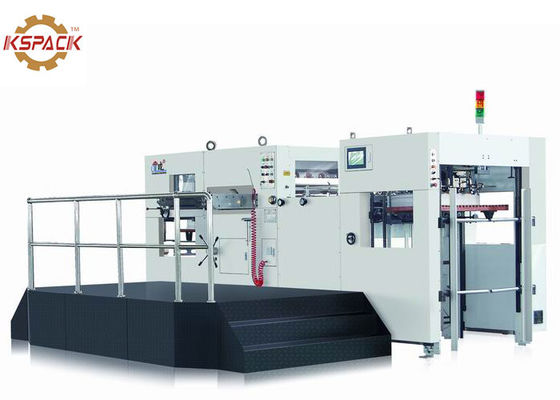

Full Automatic Die Cutting And Creasing Machine Cardboard Cutting

Full Automatic Die Cutting And Creasing Machine Cardboard Cutting

Machine Introduction :

The KSMY-1100 Automatic Die Cutting and Creasing Machine is the main equipment for making high-grade color box, plug and different shapes of ink cartons.

Components and Features:

1. Fidek structure

Fidek structure: suitable for a variety of paper, high-speed stability, and easy to adjust. ,4-8 reliable separation nozzle means so that it is more stable and more accurate high speed.

2. Positioning part: the front guide, the side guide.

Front guide: The overall swing front swinging side guide have a small impact on the paper edge, high positioning precision, with four sets of precision fiber switch(Taiwan Riko brand) to check paper in place and avoid paper wasting.

3. Die cutting part: grippers, die cutting sheet frame, die cutting steel plate, transmission structure, host bottom platform, the moving platform and the upper platform, intermittent structure, pneumatic clutch brake.

Die cutting pressure can overall regulating and can also front gripper edge regulating separately, manual reducer is convenient and labor saving.

4. Paper collecting part: Collecting paper automatically and quantitatively.

Back aligning paper, side aligning paper to ensure the automatic paper feeding orderly, the structure of paper collecting machine is simple, quick operation. Back aligning paper adjusted by electric, three times faster than the manual operating, the operation is simple and convenient.

5. Electric control part: Motor, PLC and man-machine interface, electronic control system, all kinds of safety protection device.

Motor: With imported Fuji inverter stepless speed control motor,makes the main motor saving energy, low noise. The paper feeding and collecting reducer motor choose imported Taiwan electromagnetic braking deceleration motor, with high safety performance, long service life and low running noise.

6. Lubrication system: Forced lubrication system and timing lubrication system.

Forced lubrication system: Oil pressure and flow rate adjustment is convenient, make sure that the main drive oil supply normally and will not off machine when running.

Technical Parameters:

| Model | KSMY-1100 | |

| Die cutting type | Pressed flat die cutting(Lower side is movable while upper side is unmovable) | |

| Max paper transmitting size | 1100*780mm | |

| Min paper transmitting size | 400*370mm | |

| Max die cutting size | 1090*770mm | |

| Min gripper size | 5mm | |

| Max die cutting pressure | 300N/cm² | |

| Paper processed | Ivory board | 0.1-2mm |

| Corrugated board | ≦5mm | |

| Die cutting precision | ±0.1mm | |

| Max die cutting speed | 6500 sheets/h | |

| Max feeding pile height | 1100mm(above the level) | |

| Min feeding pile height | 1100mm(above the level) | |

| Total power | 17kw | |

| Total weight | 17T | |

| Overall size |

7650*2100*2100mm (Not including the pedal) |

|

Machine Picture :

![]()