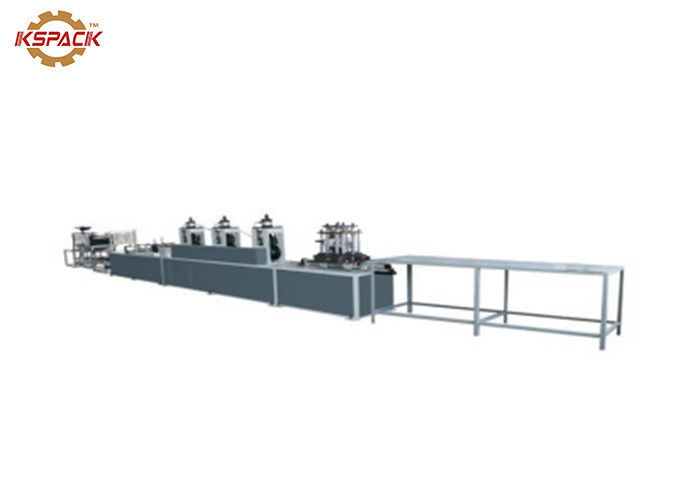

Kraft Automatic Paper Tube Machine With 25-120mm Diameter Range

-

Highlight

Kraft Automatic Paper Tube Machine

,120mm Paper Tube Machine

-

Electric EquipmentChina /import

-

MaterialKraft Paper, White Cardboard, Grey Cardboard

-

Glue TypeWater-based Glue

-

Total Power5.5KW

-

Tube Diameter Range25-120mm

-

Paper Tube Diameter20-500mm

-

Production Speed0-20 Meters Per Min

-

Tube Length Range100-1500mm

-

Place of OriginChina

-

Brand NameKSPACK

-

CertificationYes

-

Model Number350

-

Minimum Order Quantity1

-

PriceNegotiation

-

Packaging DetailsWooden

-

Delivery Time30 Work Days

-

Payment TermsNegotiation

-

Supply AbilityNegotiation

Kraft Automatic Paper Tube Machine With 25-120mm Diameter Range

Product Description:

When it comes to packaging and printing industries, the paper tube making machine is considered as an indispensable tool. This mechanical equipment rolls paper into a tube shape that serves as the core support for various products including coils, wires, and films, through processes such as paper gluing, winding, and cutting. The equipment produces paper tubes of different specifications that are widely used in packaging, printing, papermaking, and other industries.

With the help of a paper tube making machine, the process of making paper tubes has become faster and more efficient. The equipment is capable of producing these tubes in large quantities with minimal manual intervention. Apart from being efficient in terms of production, paper tube making machines are also known for their consistent quality, which ensures that every tube produced is of the same size and quality.

The use of paper tubes is not limited to just the packaging industry, as they are also used in various other applications. For instance, paper tubes are used as mailing tubes to safely transport documents, artwork, and other fragile items. Moreover, paper tubes are also utilized in industries such as textiles and construction, where they provide structural support to various products.

Overall, the paper tube making machine is an essential part of the packaging and printing industries, which has simplified the process of producing paper tubes while ensuring consistency and efficiency in production.

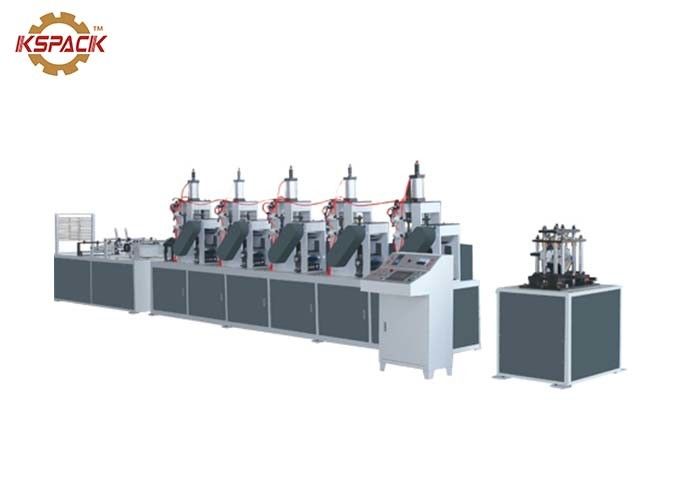

Features:

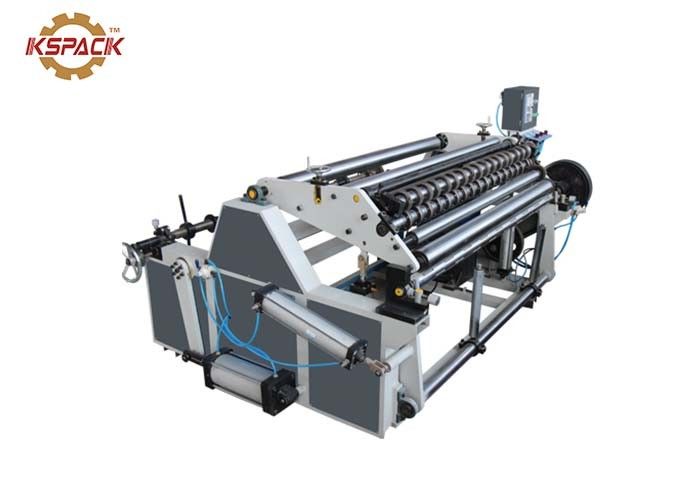

1. Automatic paper loading and feeding

The equipment is designed to automatically load and feed paper in a hassle-free manner. The Automatic paper roll alignment feature enables the equipment to align the paper roll automatically, ensuring a smooth paper feeding process. Moreover, the tension control system provides stable tension throughout the production process to prevent paper damage or slipping.

With these features, users can enjoy a hassle-free and convenient experience, as the equipment takes care of the otherwise cumbersome paper loading and feeding process.

Open in a new window2. Accurate gluing

The equipment features an advanced gluing system that enables users to accurately glue paper tubes. Its adjustable glue amount feature enables precise glue amount adjustment, ensuring uniform distribution of glue regardless of the paper and glue type. The equipment is also highly versatile, as it can adapt to a variety of glues, meeting the bonding requirements of different paper tubes.

The Precise gluing device ensures accurate gluing for different paper tubes, enabling users to produce high-quality paper tubes with ease.

Open in a new window3. Efficient winding

The equipment's adjustable winding speed feature makes it possible to adjust the winding speed according to the specific production requirements, improving the overall production efficiency. Similarly, its adjustable roll diameter allows the production of paper tubes of different diameters, further enhancing the versatility of the equipment.

The Efficient winding device guarantees an efficient winding process, enabling users to produce high-quality paper tubes with speed and ease.

Open in a new window4. Accurate cutting

The equipment's adjustable cutting length feature allows users to precisely set the cutting length according to product requirements. Similarly, the equipment's adjustable cutting angle feature can be used to adjust the cutting angle to the shape of different paper tubes, improving the accuracy of the cutting process.

The equipment's accurate cutting capability assures users of consistent and high-quality paper tubes, reducing waste and improving overall production efficiency.

Open in a new windowApplications:

One of the most versatile materials produced by paper tube making machines are paper tubes. These tubes have become an integral component in almost every aspect of our lives.

The packaging industry specifically benefits from the use of paper tubes. Their lightweight nature, strength, and recyclability make them ideal packaging containers for a wide range of products.

Paper tubes are commonly used to package a variety of food products, such as biscuits, potato chips, candies, and more. These tubes are capable of protecting the products from damage caused by squeezing and breakage.

Paper tubes are also utilized in the beverage packaging industry. They are used to package coffee, tea, beverage powder, and other drink products for convenient carrying and storage.

Paper tubes can be used for a variety of daily necessities packaging needs. From cosmetics to stationery and hardware tools, paper tubes protect products while also serving as a visually appealing display to attract potential customers.

Support and Services:

The Automatic Paper Tube Making Machine is equipped with advanced technology to ensure efficient and reliable performance. Our technical support and services include:

- Installation and commissioning

- Operator training

- Regular maintenance and servicing

- Remote technical support

- On-site technical support

- Supply of spare parts

We are committed to providing exceptional customer service and support to ensure your machine operates at peak performance and productivity.