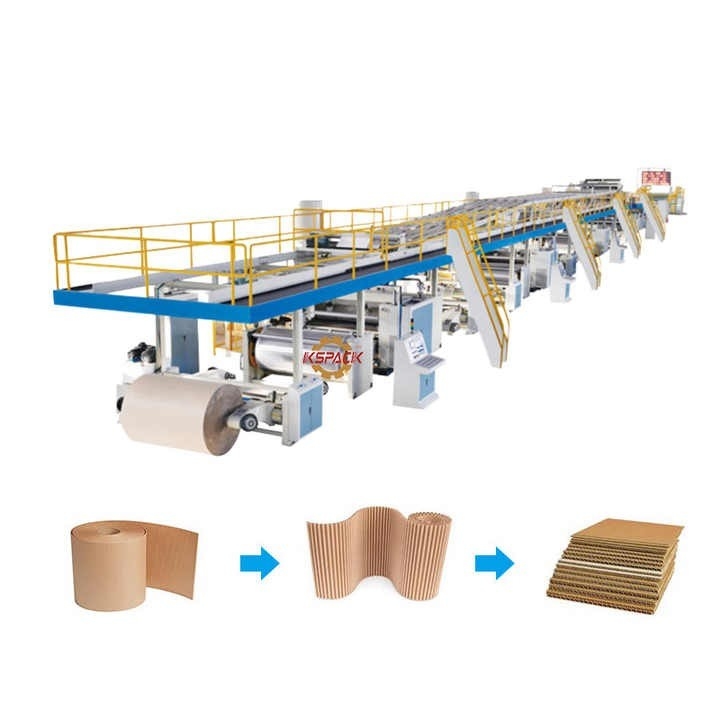

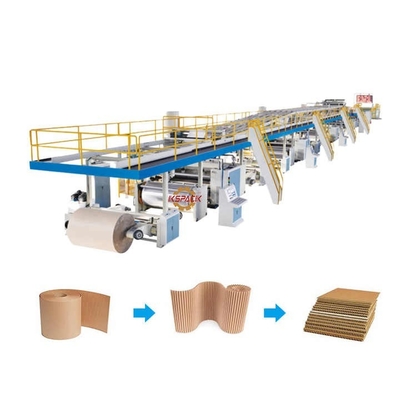

Steam Heating Packaging Line For Corrugated Paper Board Production Speed 0-200m/min

-

Highlight

Packaging Line Corrugated Board Production Line

,0-200m/min Corrugated Board Production Line

,Steam Heating Corrugated Board Production Line

-

Power Requirements380V, 50Hz

-

ConditionNew

-

KeywordCorrugated Board Production Line

-

Max Speed0-200 Min Per Min

-

Speed0-200m/min

-

TypePackaging Line

-

Heating SystemElectric,oil ,steam

-

Automatic GradeAutomatic

-

Place of OriginCHAIN

-

Brand NameKSPACK

-

Model NumberKWJ

Steam Heating Packaging Line For Corrugated Paper Board Production Speed 0-200m/min

| 1 | Maximum production paper width | 1600mm | 2 | Design production speed | 120m/min | |||

| 3 | Three-layer working speed | 100-110m/min | 4 | Five-layer working speed | 80-100m/min | |||

| 5 | Seven-layer working speed | ------------------- | 6 | Maximum order change speed | --------------------- | |||

| 7 | Slitting accuracy | ±1mm | 8 | Cross cutting accuracy | ±1mm | |||

Note | The above speed indicators must be met: the production width is 1600mm, the following paper standards are met, and the surface temperature of the heated parts of the equipment is guaranteed to be 175°C. | |||||||

| face paper indicator | 100g/㎡--180g/㎡ Ring pressure index (N.m/g) ≥ 8 (water content 8-10%) | |||||||

| Core paper index | 80g/㎡--160g/㎡ Ring pressure index (N.m/g) ≥ 5.5 (water content 8-10%) | |||||||

| inside finger | 90g/㎡--160g/㎡ Ring pressure index (N.m/g) ≥ 6 (moisture content 8-10%) | |||||||

| 9 | Corrugated combination | |||||||

| 10 | steam requirements | Maximum pressure 16kg/cm2 | Common pressure 10-12kg/cm2 | Dosage 4000kg/Hr | ||||

| 11 | electricity demand | AC380V 50Hz 3PH | Installed capacity ≈ 150KW | Common power ≈ 120KW | ||||

| 12 | compressed air | Maximum pressure 9kg/cm2 | Common pressure 4-8kg/cm2 | Dosage 1m3/min | ||||

| 13 | take up space | ≈Lmin70m*Wmin10m*Hmin5.5m (Actually subject to the audited drawings provided by Party B) | ||||||

| Specifications | device name | unit | Qty | Note |

| ZJ-V5B | Fully hydraulic | Set | 5 | Main shaft ¢242mm, hyperbolic heavy-duty rocker arm, toothed paper clamping head, multi-point brake, hydraulic drive lift, left and right translation, to the middle. |

| Rollerless paper holder | Set | 10 | ||

| R06B | Face paper preheater | Set | 2 | Roller ¢600mm, with pressure vessel certificate. Electric angle adjustment. The wrap angle can adjust the heated area of the paper within 360°. |

| R06B | Core paper preheater | Set | 2 | Roller ¢600mm, with pressure vessel certificate. Electric angle adjustment. The wrap angle can adjust the heated area of the paper within 360°. |

| SF-320B | Single facer | Set | 2 | Corrugated main roll ¢320mm, material 48CrMo alloy steel. Electric separator, electric glue adjustment. Adopt independent gearbox and universal joint transmission structure. Steam heating |

| RG-3-600 | Triple preheater | Set | 1 | Roller ¢600mm, with pressure vessel certificate. Electric angle adjustment. The wrap angle can adjust the heated area of the paper within 360°. |

| GM-12 | Glue machine | Set | 1 | The diameter of the glue roller is 245mm. Each layer is driven by an independent variable frequency motor, and the PLC adjusts the glue gap and human-machine interface. |

| ZDF | bridge | set | 1 | The main beam is 200mm channel steel, the independent frequency conversion motor drives the paper conveying, and the adsorption tensioning. Electric deviation correction. |

| SM | Double facer | set | 1 | The frame is 360 mm national standard channel steel, and the hot plate is 595 mm *16 pieces. The paper pressing part adopts a dense pressure roller design structure. Pneumatic lift. Temperature display, variable frequency motor. |

| NCBD | Slitter and creaser | Set | 1 | Tungsten alloy blade, five knives and eight lines. Electric knife adjustment, electric traverse. |

| NC-120 | NC CUT OFF | Set | 1 | Full AC servo control, energy storage brake, helical knife structure, oil-immersed gear transmission, 10.4-inch touch screen display. |

| DM | Straight stacker | Set | 1 | Two-stage frequency conversion conveying, automatic point stacking discharge, imported high-strength belt output. Paper output is standard with paper output tray. |

| ZQ | Steam system | set | 1 | Including pipeline valves, steam traps, instruments and other steam components in the equipment, the customer prepares the heat source and pipeline |

| Glue system | set | 1 |