Hydraulic Shaftless Mill Roll Stand 3 Ply Paper Corrugated Board Production Line

-

Highlight

3 Ply Corrugated Board Production Line

,Hydraulic Shaftless Corrugated Board Production Line

-

After-sales ServiceProvided

-

Automatic GradeAutomatic

-

Control SystemPLC

-

DimensionCustomized

-

InstallationProvided

-

MaterialPaper

-

PowerHigh

-

Product NameCorrugated Board Production Line

-

Production CapacityHigh

-

Service LifeLong

-

SpeedHigh

-

Voltage220V/380V

-

Warranty1 Year

-

Place of OriginCHINA

-

Brand NameKSPACK

-

CertificationCE ISO

-

Model NumberKSJ

Hydraulic Shaftless Mill Roll Stand 3 Ply Paper Corrugated Board Production Line

Hydraulic shaftless mill roll stand 3 Ply Paper Corrugated Board Production Line

※ ZJ-A electric shaftless paper holder

※ structural features:

★ the symmetrical structure can install two bundles of paper cylinders at the same time, which can be used for paper changing without stopping the machine; Mechanical drive is used to complete the actions of base paper clamping, lifting, loosening, moving, centering, left and right translation, etc.

★ pneumatic disc brake, expansion chuck.

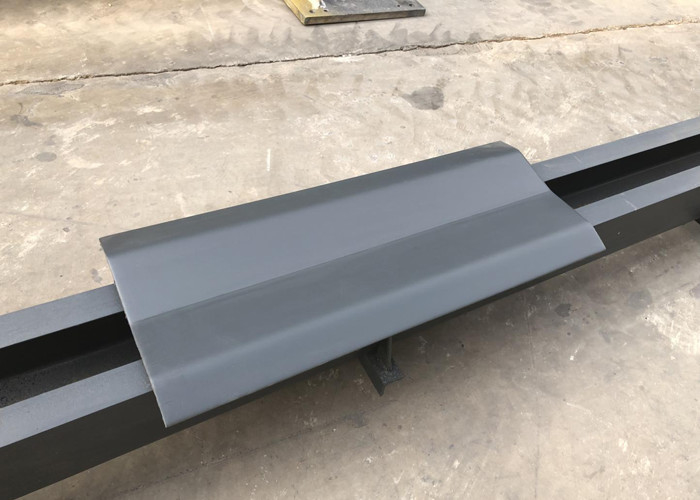

★ the track is buried as a whole. The main frame is welded with 14 channel steel and ¢ 20mm cold drawn round steel. The length of the ground rail is 5500mm.

★ each paper rack is equipped with two paper loading carts, which can load paper at the same time from both sides.

※ technical parameters:

1. Paper clamping range: maximum: 1900mm minimum: 500mm

2. Paper clip diameter: maximum: ¢ 1400mm minimum: ¢ 400mm

3. Maximum load on one side: 2000kg maximum

4. Parameters of power motor:

① Paper clamping motor 370W × 4 sets of 380V 50Hz short-time (S2) working system

② Lifting motor 1.5kw 380V 50Hz short-time (S2) working system

※ main purchased parts, raw materials and origin:

| Name of main parts | Brand or origin | texture of material |

| electric machinery | Hebei Hengshui | Shared by 3 inches and 4 inches |

| Reducer | Shandong Dezhou gold Exhibition | HT200 |

| Contactor | Schneider, France | ※ |

| Paper clip | Xusheng | texture of material |

| wallboard | Self produced | Shared by 3 inches and 4 inches |

※ paper loading trolley and guide rail

※ structural features:

★ push the web into place.

★ the track is buried as a whole. The main frame is welded with 14 channel steel and ¢ 20mm cold drawn round steel. The length of the ground rail is 6000mm.

★ each paper rack is equipped with two paper loading carts, which can load paper at the same time from both sides.

※ main purchased parts, raw materials and origin:

| Name of main parts | Brand or origin | Material model |

| Track and paper loading trolley | Tanggang or Jigang | 14 channel steel, Q235A, steel strip |

| Bearing | Ha, WA, Luo | Material model |

※ RG04 FACE (CORE) PAPER PREHEATER

※ RG-2-400 DOUBLE PREHEATER

※ structural features:

★ the preheating roller adopts the flush head design, which meets the national standard of class I pressure vessel.

★ after precision grinding, the surface of each roll is finely ground and plated with hard chromium. The surface friction is small and durable.

※ technical parameters:

1. Working width: 1800mm

2. Diameter of preheating roll: ¢ 400mm diameter of wrapped angle shaft: ¢ 70mm × two

3. Steam temperature: 150-200 ℃, steam pressure: 0.8-1.3mpa

※ main purchased parts, raw materials and origin:

| Name of main parts | Brand or origin | Material model |

| Steam swivel | Lu Guanqiu | Q235B pressure vessel plate |

| Preheating cylinder | Hangang or Jigang | |

| Bearing | Ha, WA, Luo | |

| Bearing with seat | Zhejiang Wuhuan | |

| Wrap angle axis | National standard seamless steel pipe ¢ 85 |

※ SF-280S ADSORPTION SINGLE SIDED MACHINE

※ structural features:

★ adopt cover suction structure, equipped with high-pressure strong fan. The air suction is equipped with silencing device, and the air source and electrical control are centralized in the same operation cabinet, which is not less than 1.5 meters away from the host, and the operation side is fully enclosed and covered.

★ the base and wallboard are of cast iron structure, and the thickness of wallboard is 130mm. Universal joint drive.

★ the corrugated roll is made of 48crmo alloy steel, which is quenched and tempered, medium frequency quenched, and the surface is polished. The diameter of the corrugated main roll is ¢ 280mm, and the surface hardness is more than HRC60 degrees. High temperature resistant bearings produced by Wafangdian are used for the bearings of tile rollers and pressure rollers in key parts.

★ pressure roller ¢ 284mm, surface grinding and chromium plating; The cylinder controls the up and down movement, and the material is medium carbon steel No. 45, Quenched and tempered (with buffer device).

★ pneumatically control the feeding and stripping of glue. The diameter of the rubber coating roller is ¢ 215mm. The surface is polished and engraved with 25 lines of concave reticulation. After processing, it is plated with hard chromium, and the surface of the rubber scraping roller is polished and then treated with tungsten carbide.

★ the raw materials of corrugated roll and pressure roll are provided by Zhongyuan special steel. The corrugated roll is 0.15mm high on one side, and the pressure roll is 0.075mm high on one side. Add a limit device. Use ¢ 160mm air cylinder to compress the air cylinder.

★ the preheating roll adopts seamless steel pipe ¢ 300mm made by Tiangang, and all are connected with metal hoses

※ general technical parameters:

1. Working width: 1800mm 2. Operation direction: left or right (according to the customer's factory)

3. Design speed: 100m/min 4. Temperature range: 200-260 ℃

5. Corrugated type (UV type or uvv type):

※ roll diameter parameters:

1. Corrugated roll diameter: ¢ 280mm 2. Pressure roll diameter: ¢ 284mm

3. Diameter of rubber coating roller: ¢ 216mm 4. Diameter of preheater: ¢ 320mm

※ parameters of power motor:

1. Main drive motor: 7.5kW rated voltage: 380V 50Hz continuous (S1) working system

2. Suction motor: 7.5kW rated voltage: 380V 50Hz continuous (S1) working system

※ main purchased parts, raw materials and origin:

| Name of main parts | Brand or origin | Material model |

| Wallboard and base | Self produced | HT200 |

| Swivel joint and metal hose | Lu Guanqiu | 7.5kW speed regulating motor |

| Main drive motor | Hebei Hengshui | Material model |

| Bearing | Ha, WA, Luo or Zhejiang Wanxiang | |

| Bearing with seat | Zhejiang Wuhuan | |

| High pressure fan | Shanghai Yingfa | |

| Cylinder | Zhejiang Sanzheng | |

| Contactor | Schneider, France |

※ ZDF CONVEYING BRIDGE

※ structural features:

★ this part is composed of 20 channel steel, 16 I-steel, 63 angle steel, column and other connections for the main beam.

★ there are safety guardrails, ladders (made of No. 8 small channel steel) and high-strength herringbone pedals on both sides to ensure the safety of personnel and convenient operation.

★ the surfaces of the paper pulling shaft, tension shaft, paper feeding shaft, etc. are ground and plated with hard chromium.

★ vacuum adsorption tension control, 5-inch suction pipe, plus regulating valve, the air volume can be stepless and adjustable.

★ double guide posts are used for positioning in front of the deviation correction baffle, which is driven by lead screws. The positioning is fast and accurate, and the walking is stable.

※ roll diameter parameters:

1. Diameter of paper feeding roller and tensioning roller: ¢ 130mm diameter of conveying roller: ¢ 180mm

2. Diameter of active tensioning roller: ¢ 85mm diameter of paper passing roller and paper guide roller: ¢ 111mm

3. Diameter of paper feeding towing shaft: ¢ 110mm

※ power motor and electrical parameters:

1. Single side corrugated paper lifting motor: 3.0kw 380V 50Hz continuous (S1) working system

2. Bridge adsorption fan: 3.0kw 380V 50Hz continuous (S1) working system

3. Board width motor: 250W 380V 50Hz short-time (S2) working system

※ main purchased parts, raw materials and origin:

| Name of main parts | Place of Origin | Material model |

| Main frame of bridge crossing | Produced by Tiangang or Tanggang | 20 channel steel, 18 I-steel, 12 channel steel, 63 angle steel, 60*80 square steel, etc. |

| guardrail | Tiangang products | ¢ 42mm low pressure fluid pipe |

| Paper feeding lifting belt | Made in Shanghai | PVC conveyor belt |

| Cardboard conveyor belt | Made in Hebei | Parallel conveying rubber belt |

| Adsorption frequency conversion fan | Shanghai yingfafeng Machinery Factory | |

| Frequency converter | Taiwan Delta | |

| Bearing | Ha, WA, Luo | |

| Bearing with seat | Zhejiang Wuhuan | |

| Paper width adjustment reducer | Shandong jinbuchang reducer production | |

| Paper feeding motor (frequency conversion) | Hebei Hengshui Yongshun Motor Factory | |

| Conveying roller, paper feeding roller and paper passing roller | Seamless steel pipe produced by Tiangang | |

| Contactor | Schneider, France | |

| Button | chint |

Note: all roller surfaces are ground and plated with hard chromium.

※ GM GLUING MACHINE

※ structural features:

★ after the surface of the rubber coating roller is quenched and tempered, the inner hole is processed, the dynamic balance surface is finely ground and engraved with pit type anilox, the glue coating is uniform and the glue consumption is small.

★ the surface of the rubber scraping roller is ground and plated with hard chromium.

★ the surface of other paper guide rollers is plated with hard chromium.

★ the pressure roll adopts pneumatic lifting, which is flexible and convenient to operate.

★ manually adjust the scraping clearance.

★ coating roller ¢ 215mm, leveling roller ¢ 122mm, pressing roller ¢ 122mm, preheating roller 270mm.

★ the design, production and construction process of electrical appliances comply with national standards and specifications, with low failure rate and simple maintenance.

★ manual glue mixing

※ general technical parameters:

1. Maximum working width: 1800mm 2. Operation direction: left or right (according to the customer's factory)

3. Maximum design speed: 100m/min 4. Gas source system: 0.4-0.9mpa

5. Temperature range of preheating cylinder: 150-200 ℃, steam pressure: 1.12-1.3mpa

※ roll diameter parameters:

1. Diameter of rubber coating roller: ¢ 215mm diameter of fixed paste roller: ¢ 122mm

2. Diameter of lower preheating roller: ¢ 270mm diameter of upper preheating roller: ¢ 270mm

3. Diameter of paper passing roller: ¢ 85mm

※ power motor and electrical parameters:

1. Glue roller active motor: 3kw 380V 50Hz continuous (S1) working system

2. Rubber quantity adjustment reducer: 250W 380V 50Hz short-time (S2) working system

3. Rubber pump motor: 2.2kW 380V 50Hz continuous (S1) working system

※ main purchased parts, raw materials and origin:

| Name of main parts | Brand or origin | Material model |

| Rubber coating roller and fixed paste roller | Tiangang products | 45 steel quenching and tempering |

| Preheating roll | Tiangang or Jigang | Q235B container plate |

| Bearing | Ha, WA, Luo or Zhejiang Wanxiang | |

| Bearing with seat | Zhejiang Wuhuan | |

| Pneumatic components | Zhejiang Sanzheng | |

| relay | Schneider, France | |

| Main reducer | Shandong Jinzhan |

※ SM DOUBLE SIDED MACHINE

※ structural features:

★ the surface of the heating plate is ground. The width of the heating plate is 595mm. There are 9 heating plates in total, and the length of cooling and shaping is 4 meters.

The heating plate is made of container plate, which meets the national class I pressure vessel standard, and is attached with pressure vessel certificate and inspection certificate.

★ the hot plate adopts dense gravity pressure roller structure. The pressure roll lifting adopts pneumatic structure.

★ the heat conduction piping of the heating plate is divided into seven sections to control the temperature, with temperature display.

★ the upper cotton belt adopts double air cylinder S-type cotton belt tensioner.

★ the lower belt adopts an S-shaped manual deviation correction and tensioning mechanism, which has a simple and practical structure. The lower belt has a set of manual fine adjustment.

★ the surface of the drive roller is attached with wear-resistant image glue, which is in herringbone structure and has medium height to ensure the smooth output of the paperboard.

★ the main drive motor is a variable-frequency speed regulation motor, with large low-speed torque, wide speed regulation range, reliable use and simple maintenance.

★ the inside of the hot plate is a diaphragm isolation structure, which makes the steam flow in an S-shaped direction, and the separation function of steam and water is obvious, which improves the utilization rate of steam.

※ general technical parameters:

1. Temperature requirement: 160-200 2. Air supply pressure: 0.6-0.9mpa

3. Cooling finalization length: 4m number of heating plates: 9

※ roll diameter parameters:

1. Diameter of upper drive rubber roller: ¢ 600mm diameter of lower drive rubber roller: ¢ 600mm wrapped with wear-resistant rubber

2. Diameter of front driven belt roller: ¢ 320mm diameter of rear shaped driven belt roller: ¢ 176mm

3. Diameter of pressing roller: ¢ 85mm and ¢ 70mm diameter of setting idler: ¢ 86mm

4. Diameter of upper belt tensioning roller: ¢ 155mm diameter of upper belt deviation adjusting roller: ¢ 124mm

5. Diameter of lower belt pressing shaft: ¢ 130mm diameter of lower belt supporting roller: ¢ 130mm

Note: all roller shaft surfaces are hard chrome plated after grinding.

※ power motor and electrical parameters:

1. Power of main drive motor: 30kW 380V 50Hz continuous (S1) working system

※ main purchased parts, raw materials and origin:

| Name of main parts | Brand or origin | Brand or origin |

| Main skeleton | Profiles produced by Tiangang or Laigang | Profiles produced by Tiangang or Laigang |

| Heating plate | Tiangang or Jigang | Tiangang or Jigang |

| Main drive motor | Hebei Hengshui | Hebei Hengshui |

| Cotton ribbon | Shenyang | Shenyang |

| Contactor | Schneider, France | Schneider, France |

| Hydraulic station | Hebei | Hebei |

| Bearing | Ha, WA, Luo | Ha, WA, Luo |

| Drive wallboard | Hebei | Hebei |

| Pneumatic components | Zhejiang sono CSM | Zhejiang sono CSM |

| Photoelectric switch | Korean Autonics (otonix) | |

| Bearing with seat | Zhejiang Wuhuan |

ZQS THIN KNIFE LONGITUDINAL CUTTING INDENTATION MACHINE

※ structural features:

★ it overcomes the phenomenon that the conventional double knife type, slitting and pressing machine collapses the paperboard during cutting, and the cutting board is smooth and the quality is significantly improved.

★ the whole machine can be moved left and right, and adjusted by cycloid reducer.

★ it is convenient to adjust the cutter and pressing line, with an error of ± 0.5mm. There is an automatic knife sharpening device, which can realize various functions such as regular knife sharpening and interval knife sharpening.

★ this machine adopts 5 knives and 8 pressing lines, and the blade is made of tungsten alloy steel, with a service life of no less than 3million running meters.

※ general technical parameters:

1. Maximum working width: 1900mm 2. Maximum mechanical speed: 100m/min

3. Mechanical configuration: 5 knives and 8 wires 4. Minimum paper cutting width: 135mm

※ power motor and electrical parameters:

1. Cutter line motor: 0.4KW 2. Drive motor: 4.0kw

※ main purchased parts, raw materials and origin:

| Name of main parts | Brand or origin | |

| Variable frequency motor | Hebei Hengshui Yongshun Motor Factory | |

| Bearing | Harbin | |

| Bearing with seat | Zhejiang Wuhuan | |

| relay | Schneider, France | |

| Proximity switch | Omron Japan | |

| Solenoid valve | Taiwan Yadeke | |

| Left and right traverse motor | Shandong Jinzhan reducer production |

※ NC-100 COMPUTERIZED STRAIGHT KNIFE CROSS CUTTING MACHINE

※ structural features:

★ it can store 200 groups of orders, change the paper cutting specification quickly and accurately, change the order without stopping the machine, and realize computer networking, which is convenient for production management.

★ the cutter shaft transmission gear is made of precision forged steel and quenched with high frequency to realize backlash free transmission. The advanced keyless connection mode is adopted with high transmission accuracy.

★ the blade of the cross cutting machine adopts the structure of inlaid steel straight knife. Scissors shear, small shear force, long blade life.

★ the front and rear paper feeding wheels adopt the sun wheel paper pressing method, which is stable in transportation and uniform in pressure, and is not easy to crush the plate or cause blockage.

★ this model is energy storage braking (non energy consumption braking), so it consumes low and medium energy in the production process. The average power consumption is 1/3 of that of ordinary NC cut-off machines, saving more than 70% of electricity and achieving the goal of saving money.

★ precision adjustable gapless gear ensures accurate meshing of the knife edge and balanced operation.

★ independent oil pump and filter are used together with two groups of copper tubes distributed in each gear position for oil supply, lubrication and cooling.

★ knife roller: made of high-quality precision forged steel, after balance treatment, it has good stability.

※ general technical parameters:

1. Maximum working width: 1900mm 2. Operation direction: left or right (determined according to the customer's workshop)

3. Maximum mechanical speed: 100m/min 4. Mechanical configuration: computer spiral cutter cross cutting

5. Minimum paper cutting length: 500mm 6. Maximum paper cutting length: 9999mm

7. Paper cutting accuracy: constant speed ± 1mm, non-uniform speed ± 2mm 8. Equipment size: lmx4.2*wmx1.2*hmx1.4

9. Single machine weight: 3000kg maximum

※ roll diameter parameters:

1. The center distance between the upper and lower knife axes of cross cutting: ¢ 216mm 2. The diameter of the front and lower conveying rollers ¢ 156mm

3. Diameter of rear lower conveying roller: ¢ 156mm 4. Diameter of paper pulling roller: ¢ 160mm

5. Diameter of output sun gear: ¢ 160mm

Note: all roller shafts are ground, and the surface is plated with hard chromium (except the upper and lower knife shafts).

※ power motor and electrical parameters:

1. Power of main drive motor: 11kw full AC synchronous servo

2. Front and rear paper feeding motor power: 3kw (variable frequency speed regulation)

3. Lubricating oil pump motor power: 0.25kw

※ main purchased parts, raw materials and origin:

| Name of main parts | Place of Origin | Material model |

| Full AC servo motor | Hebei Hengshui Yongshun Motor Factory | 11KW |

| Paper feeding frequency conversion motor | Hebei Hengshui Yongshun Motor Factory | The upper and lower knife roller bearings adopt Japanese NSK |

| Bearing | Ha, WA, Luo | Material model |

| Timing belt | Oppi Optibelt, Germany | |

| Tension sleeve | Xianyang transcendence | |

| Bearing with seat | Zhejiang Wuhuan | |

| Contactor and relay, intermediate relay | Schneider, France | |

| Proximity switch | Omron Japan | |

| Flying shear servo control system | Domestic INVISTA | |

| Motion control panel | Yingweiteng | |

| Rotary encoder | Wuxi Ruipu | |

| Paper feeding frequency converter | Yingweiteng | |

| interface | Yingweiteng | |

| Sun wheel | Made in Shenzhen, China | |

| Pneumatic components | Japan SMC or Taiwan adek |

※ D M T-80 right angle stacker

※ structural features:

★ 16 channel steel is used for welding. The size of the cardboard is adjusted electrically, the horizontal output of the cardboard is controlled pneumatically, and the conveying speed is electrically adjustable.

★ when the number or height of cardboard reaches the required level, the cardboard is removed by foot switch control.

★ the longitudinal paper is conveyed by wide conveyor flat belt.

※ general technical parameters:

1. Maximum stacking length: 3000mm 2. Maximum stacking height: 200mm

※ power motor and electrical parameters:

1. Main conveying motor: 2.2kW variable frequency motor

2. Horizontal output motor: 1.5kw three-phase asynchronous motor

3. Traveling motor: 0.75KW three-phase asynchronous motor

ZJZ glue making station system

※ structural features:

★ provide starch adhesive for single-sided corrugating machine, double gluing machine and other gluing equipment.

★ horizontal glue making machine can prepare main glue and carrier glue at the same time, and mix and stir, with a large amount of glue.

★ the glue liquid in the storage barrel of the glue making room is transported to the storage barrel of each glue using equipment by the glue pump to provide glue liquid for the equipment.

★ the storage barrel and glue supply barrel are equipped with mixing devices to avoid the precipitation and agglomeration of glue liquid.

★ the glue making device is composed of carrier tank, main tank, storage tank, glue delivery pump, glue return pump, etc.

★ the glue making system adopts circulating glue supply, the remaining glue flows into the glue return square barrel, and the liquid level floating ball is automatically controlled. The glue in the glue return square barrel is pumped back to the storage barrel of the glue using equipment for circulating glue supply, so as to save the glue and prevent the glue from gelatinizing and caking in the glue tray.

★ after the work is completed, the remaining glue of each glue using equipment is divided, and the glue pump of the main pipeline is pumped back to the storage barrel of the glue room for next use.

★ be responsible for technical guidance and teach the preparation process of adhesives.

50Hz※ general technical parameters:

1. Horizontal main rubber mixer: 1 set 2. Carrier rubber mixer: 1 set

3. Glue storage mixer: 1 set 4. Glue barrel on double glue applicator: 1 piece

5. Glue return barrel of double glue applicator: 1 piece 6. Glue barrel on single-sided machine: 2 pieces

7. Glue return barrel of single-sided machine: 2 pieces 8. Glue conveying pump: 4 sets

※ rubber barrel diameter parameter:

1. Horizontal main rubber mixer: 1250mm × 1000mm × 900mm

2. Diameter of carrier rubber mixer: ¢ 800mm × 900mm

3. Diameter of double glue barrel: ¢ 800mm × 1000mm single-sided machine rubber barrel: ¢ 800mm × 1000mm

4. Storage rubber barrel diameter: ¢ 1200mm × 1200mm

※ power motor and electrical parameters:

1. Horizontal main rubber mixer: 3kw 380V 50Hz

2. Carrier rubber mixer: 2.2kW (ordinary three-phase) 380V 50Hz

3. Glue conveying pump motor: 2.2kW (ordinary three-phase) 380V 50Hz

4. Storage rubber barrel motor 1.5kw (ordinary three-phase) 380V 50Hz

※ main purchased parts, raw materials and origin:

| Name of main parts | Place of Origin | |

| Motors | Hebei Hengshui electric machine factory | |

| Glue pump | Botou products in Hebei | |

| Skeleton profile | Tanggangchan |

![]()