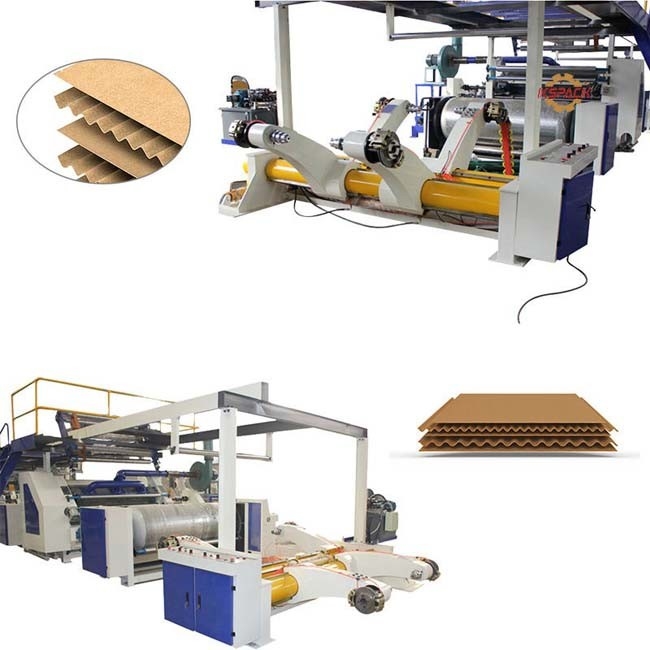

Compact Structure Corrugated Board Production Line 1 - 5 Layer

-

Highlight

Compact Corrugated Board Production Line

,Corrugated Board Production Line 5 Layer

,Compact Structure Corrugated Board machine

-

ConditionNew

-

After-sales Service ProvidedEngineers Available To Service Machinery Overseas

-

Voltage380V

-

Warranty1 Year

-

Product TypePaper Plate Machine

-

Dimension(l*w*h)Configuration

-

Processing TypeEmbossing Machine

-

NameCorrugated Board Production Line

-

Place of OriginCHINA

-

Brand NameKSPACK

-

CertificationCE ISO

-

Model NumberKSJG

-

Minimum Order Quantity1 SET

-

PriceNegotiate

-

Delivery Time5-8 work days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Supply Ability1 set per 30 days

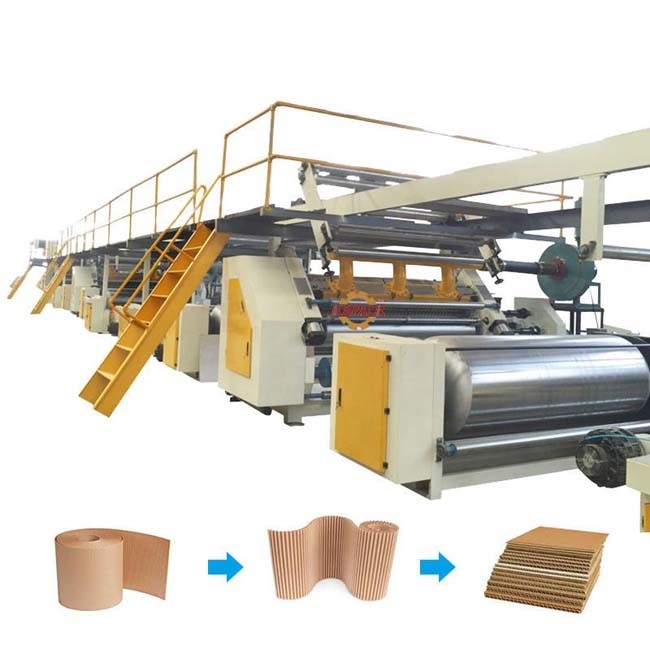

Compact Structure Corrugated Board Production Line 1 - 5 Layer

Compact Structure Corrugated Board Production Line 1 - 5 Layer

Corrugated Board Production Line Description

Complete corrugated paperboard production line is compose of shaftless mill roll stand,fingerless type single facer

(vacuum suction type). preheater,double bridge,gluer machine,double facer machine,cut off machine,slitter scorer machine,stacker and glue making system. Our company to absorb advanced technology from other countries,we get feed back from our users and on the base of our experience more years for develop the new production. The feature of our machine;high automatization,easy operation&maintenance,high efficiency,good quality of paperboarf,compact structure and nice appearance.

Single Facer Machine

1. Adopt the cover style adsorb structure ,match with high pressure winder,winder match with quiter ,air andelectrical control centrated in the operation work table, distance with main machine1.5 m.main machineoperation side all have the cover.

2. Machine seat with wallboard all case iron, the thickness of wall board 130mm,adopt the alone gearbox,andgimbal transmission.

3. Corrugated roller adopt 48 crmo ,alloy steel,after laser hardening.

Surface grinding,corugated roller diameter 280mm,surface hardness HRC60,main part bear of the corrugatedroller ,and pressure roller with stand high temperature.

Hydraulic Mill Roll Stand

Symmetrical structure can install two rolls of paper at the same time and continually change paper roll;It adopts motorized control clamping, loosen,up-down, movement, contraposition, translation.Equipment was made of HT200-wide casting

It adopts pneumatic braking.

Adopt hydraulic drive to complete the paper clamping, loosen, remove for the medium, translation left and rightand others,the lifting of the paper adopts hydraulic drive.Brake adjustable adopts multi point braking system.

Top(core) Paper Preheater

In accordance with national standard category pressure vessel,and with the pressure vessel certificate. The roll surface after precision grinding, fine grinding and hardchromium plating processing, surface friction,durable. Electric adjustable angle, angle can rotate in the range of 360°,and adjust the paper preheat area.

Double Glue Machine

- After the glue roller surface after quenching inner hole machining, grinding and dynamic balancing surfaceengraved with pit style textured, coating evenly, less consumption of plastic.

- doctor roller surface by grinding and hard chromium plating.

- Other guide rollers with hard chrome plated.

- Pressure roller with pneumatic lift, easy operation.

- Manually adjust scraping gap.

- Glue roller4215mm,Doctor roll4122mm,press paper roller4122mm,preheat roller 270mm.

- Electrical design,construction production process, follow the national standards, low failure rate, easymaintenance.

Thin Knife Slitting

Overcome the conventional type of pole, cutting pressure lines appear when collapsed cardboard cutphenomenon, cutting board smooth, quality has improved significantly. The whole machine can remove left and right,cycloid reducer to adjust. Cutter and easy to adjust the pressure line, the error ± 0.5mm, automatic sharpening device, you canachieve timing Brothers, with intermittent Brothers and other features. The machine adopt five knives eight lines,the blade is made of tungsten alloy steel, the using life is notless than 3 million running meters.

Paper Sheet Delivery And Side Conveyor

Adopted on the 16th channel welded.Electric adjustment of cardboard the size of the lateral outputpneumatic control board, electrically adjustable conveyor speed. Cardboard sheets to the desired number or height requirements will be controlled by a foot switchout of cardboard. Vertical bin using wide flat belt conveyor transport.

Glue Station System

Provide the starch adhesive to the corrugated single facer,two glue machine and some other gluingequipment. Horizontal glue machine can meanwhile matched with main body glue and carrier glue, and mixing,glue large. Making room storage barrels adhesive solution was to use the glue pump rubber equipment storagebarrels, adhesive solution for equipment. Storage barrels, plastic barrels with mixing device, avoid glue solution precipitation agglomerate. System unit with carrier vessel, main tank, storage tank, and send the glue pump, the back glue pump,etc.

|

Hydraulic shaftless mill roll stand |

Set |

3 |

Main shaft ¢242mm, hyperbolic heavy-duty rocker arm, tooth-type paper clamping head, multi-point brake, hydraulic drive lift, |

|

Paper trolley |

set |

6 |

|

|

Top paper preheat cylinder |

Set |

1 |

Roller ¢900mm, including pressure vessel certificate. Electric adjustment of wrap angle. The wrapping angle can adjust the heated |

|

Core paper prehear cylinder |

Set |

1 |

Roller ¢900mm, including pressure vessel certificate. Electric adjustment of wrap angle. The wrapping angle can adjust the heated |

|

Fingerless type single facer |

Set |

1 |

The corrugated main roller is ¢320mm, and the material is 48CrMo alloy steel. Tungsten carbide treatment, tile roller module type |

|

Double preheater |

Set |

1 |

Roller ¢900mm, including pressure vessel certificate. Electric adjustment of wrap angle. The wrapping angle can adjust the heated |

|

glue machine |

set |

1 |

The diameter of the glue roller is 268mm. Each layer is driven by an independent frequency conversion motor, and PLC adjusts the |

|

Conveyor bridge |

set |

1 |

The main beam is 200mm channel steel, and the independent frequency conversion motor drives the paper pulling and conveying, and |

|

Double facer |

set |

1 |

Frame 360 mm national standard channel steel, hot plate 595 mm *14 pieces, intensive roller design structure. Pneumatic lifting, |

|

Lifting thin knife slitting and creasing machine |

set |

1 |

Tungsten alloy blade, five-knife eight-wire type, electric knife adjustment, electric wire adjustment. Electric traverse. |

|

Computer spiral knife |

set |

1 |

Full AC servo control, energy storage brake, spiral knife structure, oil-immersed gear drive, 10.4 inch touch screen display. |

|

Three-section right angle stacker |

set |

1 |

Three-stage frequency conversion conveying, automatic counting and stacking discharge, imported high-strength belt output, and |

|

Glue station system |

set |

1 |

The pipeline customer shall prepare by himself. The glue making device is composed of a carrier tank, a main tank, a storage tank, |

|

Air source system |

set |

1 |

The customer's own gas source. |

|

Steam system |

set |

1 |

Including steam components such as pipeline valves, traps, and meters in the equipment, the customer shall prepare the heat source |

![]()