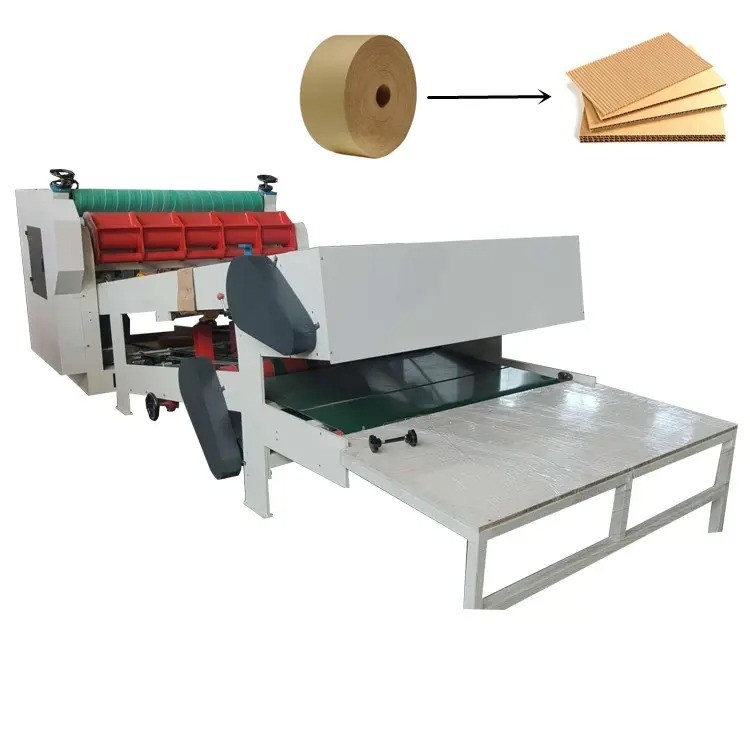

Paper Industry 3Ply Wall Corrugated Paperboard Production Line 330KW

-

Highlight

3Ply corrugated paperboard production line

,Corrugated Paperboard Production Line 330KW

,corrugated cardboard production line 330KW

-

ConditionNew

-

Voltage380V,220V/380V

-

Warranty1 Year

-

Product TypePaper Plate Machine

-

Weight30t

-

Dimension(l*w*h)Configuration

-

Processing TypeEmbossing Machine

-

CertificationCE

-

Power(w)330KW

-

Production Capacity10

-

Raw MaterialWood Pulp

-

Output PaperKraft Paper,corrugated Paper,Paperboard,cement Bag Paper,test Liner Paper

-

Capacity30t/d

-

Product NameThe Best Automatic 4 Color 3/5/7 Ply Corrugated Board Production Line

-

ColorOptional

-

ApplicationPaper Industry

-

Working Speed200

-

Place of OriginCHINA

-

Brand NameKSPACK

-

CertificationCE ISO

-

Model NumberKSJ

-

Minimum Order Quantity1SET

-

PriceDollar 5000USD-25000USD

-

Delivery Time5-8weeks

-

Payment TermsL/C, D/A, D/P, T/T

-

Supply Ability1 set 40per days

Paper Industry 3Ply Wall Corrugated Paperboard Production Line 330KW

Equipment one : Electric mill roll stand

Electrical control model mill roll stand (Cast iron type)

The paper stand machine support arm can be made cast iron or box iron

1) Structural features

★ symmetrical structure can be installed at the same time two bundles of paper tube, can be used for non-stop machine to change the paper

★ electric o clamping, release, moving on the left and right

★ brake adjustment using disc plate system.

★ with two-stage automatic expansion of the paper clip, clamp head size 3 inch

2)Technical parameters

1. paper stand active model: Mechanical electrical

2.clamp paper scope : max 1400mm 1800mm , min 100mm

3.clamp diameter : max ¢1400mm

4.single side max load weight : 1500kgs

5.power : 380 volt ,50hz

6.Turn over motor power : 1.5kw /set clamp motor power : 0.75kw 4 set

7.manual brake model ( option pneumatic brake model )

8.electric brand : DELIXI CHIT

9. machine weight : 2.3T

3)Mainly purchased parts, raw materials and origin

| Name of main parts | Brands or place of origin | material |

| Main shaft | Self made | HT200 |

| arm | Self made | HT200 |

| Wall board | Jigang produce | Q235A |

| Bearing | Ha ,wa ,luo | |

| Electrical | Delixi ,chit |

Equipment two : SF-280 vacuum single facer machine-1400mm

※characteristics:

1. Adopt the cover style adsorb structure ,match with high pressure winder , winder match with quiter ,air and electrical control centrated in the operation work table, distance with main machine1.5 m .main machine operation side all have the cover.

2. Machine seat with wallboard all case iron , the thickness of wall board 130mm ,adopt the alone gearbox ,and gimbal transmission

3.Corrugated roller adopt 48 crmo ,alloy steel ,after laser hardening

Surface grinding , corugated roller diameter 280mm ,surface hardness HRC60 ,main part bear of the corrugated roller ,and pressure roller with stand high temperature

4.Pressure roller diameter324mm ,surfacer grinding and chormeplated ,cylinder control move up and down ,material medium carbon steel 45#,hardening and tempering (with cushioning device)

5. Pneumatic control supply or reback the glue ,coating glue roller diameter 215mm ,surface after grinding ,carved 25 line steel pit anilox , then chorme plated , even glue roller after grinding then chorm plated .

6. Corrugated roller ,pressure roller material suppled by zhongyuan tegang, corrugated roller single side have 0.15mm middle height, pressure roller single side 0.075mm middle height. Add the limit device,

Press clycinder use diameter 160mm

Preheater diameter 320mm ,use the steamless steel ,connect by steel soft tube

Note :

Electric adjust glue model

Universal joint drive

※techinicalparameter :

1,work width:1400mm

2,operate direction :left or right ( according the cletns workshop design)

3,temperature scale:160—200℃

4,air compressor:0.4—0.9Mpa

5,stear pressure:0.8—1.3Mpa

6,corruated style (Uvstye or UVVstyle):

※roller diameter parameter:

1,corrugated roller diameter : ¢280mm

2,pressure roller diameter: ¢324mm

3,glue coating roller diameter: ¢215mm

4,preheater diamter: ¢320mm

| Working Width | 1400mm | |||||

| Heating method | electrical heating , steam heating or oil heating you can choose | |||||

| Speed | Around 40m/min for electric heating , 60-70m/min for oil heating and steam heating | |||||

| Compress-air pressure | 0.4-0.9MPa | |||||

| Flute type | Standard flute | UVE Flute | ||||

| Standard spec. | A,B,C,E,F | |||||

| For other type and model, we can produce as customer’s requirement. | ||||||

| Corrugated roll diameter (mm) | 280 | |||||

| Wall Thickness (mm) | 130 | |||||

| Type | Vacuum Absorb | |||||

| Roller material | 48CrMo alloy, Heat treated | |||||

| Machine Size (mm) | 3050*1300*1700 | 3300*1300*1700 | 3550*1300*1700 | 3800*1300*1700 | 4050*1300*1700 | |

Equipment Three : PLC control sheet cutter with stacker

Cutter part :

Computer sheet cutter that is equipment for slit and cross cut the 2 ply corrugated board, this machine change order time short ,cut accurte is high ,work speed is higher ,change order quick will waste the paper less ,

The machine uses the touch screen design ,using the variable frequency motor speed control, servo drive control, reduce failture rate of the mechanical transmission when use the machine ,cutting accuracy more accurate.

Stacker part :

| Max width of cardboard | 1800 mm | Length of cardboard | 10mm-2400mm |

| Times of cutting cardboard | 80 knives /mins | Thickness | 50-500g |

| motor | 4.0w | ||

| machine size | 2700x3200x1500 | tolerance | ±1mm |

| Touch screen | Weilun | Frequency | alfa |

| Frequency motor | 2 set | Knives | Nanjing |

| Bearing | FK | Electrical | Chit |

Single facer sheet stacker that is corollary equipment with sheet cutter machine , sheet cutter make the single facer board cut to the requirement size , then use the stacker collect the board , reduced the work labor.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()