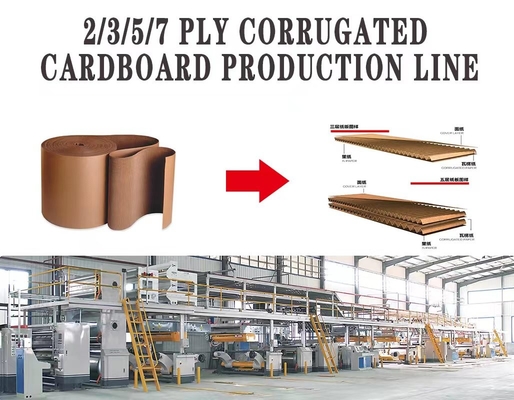

5 Ply 1800mm Corrugated Cardboard Production Line 100 Speed Full Automatic

-

Highlight

1800mm corrugated board production line

,5ply corrugated cardboard production line

,1800mm corrugated cardboard production line

-

Place of OriginChina

-

Brand NameKSPACK

-

CertificationCE ISD

-

Model Number1800

-

Minimum Order Quantity1 set

-

Price150000 USD/ ton

-

Packaging Detailswooden case and wooden pallet

-

Delivery Time70-80 work day

-

Supply Ability10 Set /Month

5 Ply 1800mm Corrugated Cardboard Production Line 100 Speed Full Automatic

5 ply 1800mm 100 speed full automatic corrugated board making carton box machine

1. Introduction

The corrugated board production line is the abbreviation of the corrugated board production line. It is a streamlined operation line composed of corrugated rolls, gluing, bonding, dividing and pressing, cross-cutting into specifications, and finally stacking and outputting. For example, a single-faced corrugated paper production line is usually composed of a roll paper support, a single-faced corrugated board forming machine, and a rotary paper cutting unit. The roll paper material and potato or corn starch binder are used to continuously produce and cut into the required specifications. For corrugated cardboard, the cardboard produced does not need to be dried or dried. At the same time, it can be used in conjunction with a glue machine or a veneer to produce corrugated cardboard with more than three layers.

2.Component

| Model | Name | Unit | Qty | Mark |

| ZJ-V5B | Full hydraulic | Set | 5 | Main shaft ¢242mm, hyperbolic heavy-duty rocker arm, tooth-type paper clamping head, ventilated disc type multi-point brake, hydraulic drive lift, left and right translation, centered. |

| DXC | Shaftless paper holder | Set | 10 | The ground rail trolley has a length of 6000mm with double guide rails and is welded by a middle plate. . |

| RG-600 | Loading trolley | Set | 2 | Roller ¢600mm, including pressure vessel certificate. Electric adjustment of wrap angle. The wrapping angle can adjust the heated area of the paper within the range of 360°. |

| RG-600 | Facial paper preheating cylinder | Set | 2 | Roller ¢600mm, including pressure vessel certificate. Electric adjustment of wrap angle. The wrapping angle can adjust the heated area of the paper within the range of 360°. |

| SF-280 | Core paper preheating cylinder | Set | 2 | The corrugated main roll is ¢280mm, and the material is made of 48CrMo alloy steel. Universal joint drive, steam heating method. |

| RG-600 | Adsorption | Set | 1 | Roller ¢900mm, including pressure vessel certificate. Electric adjustment of wrap angle. The wrapping angle can adjust the heated area of the paper within the range of 360°. |

| GM | Single side machine | Set | 1 | The diameter of the glue roller is 240mm. Each layer is driven by an independent frequency conversion motor, and the glue gap is adjusted electrically. |

| TQ | Triple preheater | Set | 1 | The main beam is 200mm channel steel, and the independent frequency conversion motor drives the paper pulling and conveying, and the suction type tensioning. Electric deviation correction. |

| SM | Second floor | Set | 1 | Frame 360 mm national standard channel steel, hot plate 595 mm *16 pieces, intensive roller design structure. Pneumatic lifting, automatic correction, temperature display, frequency conversion motor. |

| NCBD | Glue machine | Set | 1 | Tungsten alloy blade, five knives and eight lines. Electric knife adjustment and electric lateral movement. |

| NC | Conveying across the bridge | Set | 1 | Full AC synchronous servo control, energy storage brake, spiral knife structure, helical gear transmission, lubricating oil pressure protection, 10.4-inch touch screen display. |

| DM | Double-sided machine | Set | 1 | The frequency converter controls the delivery and points. Horizontal output PLC memory function. |

| ZJZ | Thin knife | Set | 1 | The pipeline customer shall prepare it by himself. The glue making device is composed of a carrier tank, a main tank, a storage tank, a glue feeding pump, and a glue returning pump. |

| QU | Slitting and creasing machine | Set | 1 | The customer prepares its own gas source. |

| ZQ | Computer Spiral Knife | Set | 1 | Including steam components such as pipeline valves, traps, meters, etc. in the equipment, and customers provide their own heat sources and pipelines. |

| 1. Steam heating system: It is recommended to equip a 4000Kg/Hr steam boiler with steam pipes with a pressure of 1.25Mpa. |

| 2. Air compressor, air pipeline, glue delivery pipeline. |

| 3. Connect the power supply and wires to the operation cabinet and line pipes. |

| 4. Water sources, water pipelines, buckets, etc. |

| 5. Water, electricity and gas foundation plane installation civil works. |

| 6. Raw paper, corn (tuber) starch, industrial caustic soda, borax and other materials for trial run. |

| 7. Engine oil, lubricating oil, hydraulic oil and grease for equipment. |

| 8. Food and accommodation for installation and commissioning personnel. And provide installation workers to cooperate with the installation. |

4.Machine photo

![]()