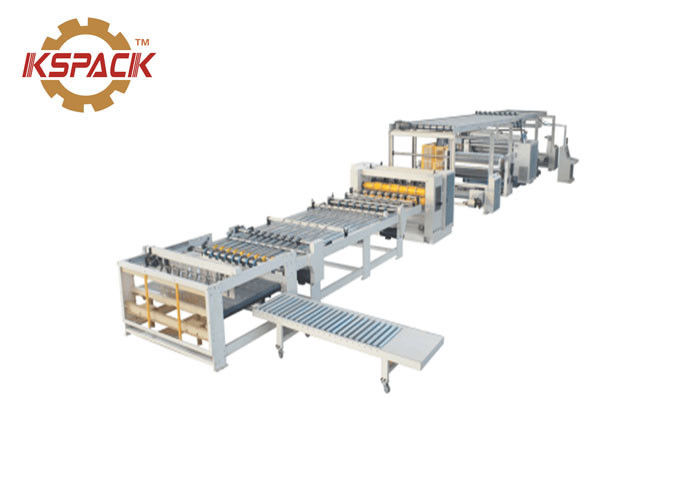

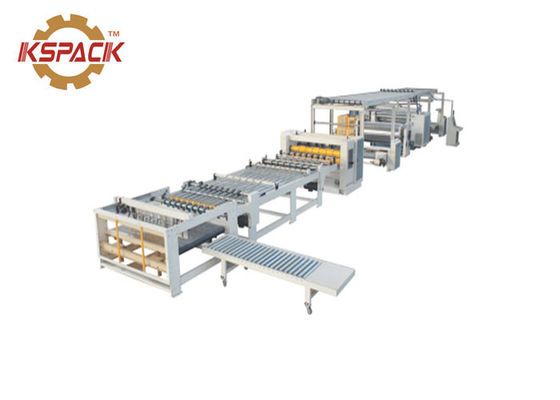

Automatic 5 Ply Cardboard , Corrugated Carton Production Line 1600mm

-

Highlight

5 ply cardboard

,corrugated cardboard production line

-

NameAutomatic 5 Ply Cardboard , Corrugated Carton Production Line 1600mm

-

Service1 Year Warranty

-

FeatureEasy Operation

-

Item5 Ply Cardboard , Corrugated Carton Production Line

-

WeightCustomize

-

Degreeof AutomationFully Automatic

-

Place of OriginChina Hebei

-

Brand NameKingsun

-

CertificationCE

-

Model NumberWJ

-

Minimum Order Quantity1 Set

-

PriceNegotiable

-

Packaging DetailsWrapped in plastic film and placed in wooden box

-

Delivery Time7-9 work days

-

Payment TermsL/C, T/T

-

Supply Ability1 set 40-60 per days

Automatic 5 Ply Cardboard , Corrugated Carton Production Line 1600mm

Automatic 5 Ply Cardboard , Corrugated Carton Production Line 1600mm

Production line main parameter and requirement

Board max width :1800mm

Design speed :80m/min

Work speed :60m/min(3ply)

Remark: the speed trail paper use must appropriate under need .( equipment temperature can not less 172℃

Base paper not less B class

Mositure: 11%±2%

face paper :100—250g/m2 ﹡core paper :100--250g/m2

flute paper:100—200g/m2

Flute style : A. C, B .E( or according to the client need )

Steam requirement

steam volume 1500—2000Kg/Hr ﹡max pressure :1.2Mpa

popular pressure:0.8-1.1Mpa

Power :According clients need

Machine total power :about 80KW

Actual electrical us:about 60KW(total speed)

Ground area :about 38m×10m×5m

paper feeding out :according the buyer workshop to left or right

equipment use ,can use A,B,C class china base paper or import base paper

Parameter

| Model | Equipment name | Unit | QTY | REMARK |

| ZJ-F-1800 | Mill roll stand | set | 3 | internal expansion brake, manual brake ,mechnicial motor control up and down , left and right and centering |

| railing | set | 6 | Length:4510mm ,adopt weld by medium steel(10mm) | |

| RG-1-600 | Preheater | set | 1 | Dia 600mm,have the pressure vessel certificate,electrical adjustment the angle , scale during 60-270°adjust the paper heat area |

| RG-1-600 | Core Preheater | set | 1 | Dia 600mm,have the pressure vessel certificate,electrical adjustment the angle , scale during 60-270°adjust the paper heat area |

| SF-280S | Fingerless single facer | set | 1 | Diameter of corrugating roller ¢280mm,,material 52CrMoalloy steel,gimbal transmission. |

| RG-2-600 | double preheater | set | 1 | Dia 600mm,have the pressure vessel certificate,electrical adjustment the angle , scale during 60-270°adjust the paper heat area |

| GM-B | Doube glue machine | set | 1 | Glue roller diameter ¢242mm,anilox of surface roller .manual adjustment the coat size ,press roller adopt the pneumatic rise and down |

| DF | Feeding bridge | 1 | 1 | Vacumme suction system ,Motorized left-right adjustment |

| SM-S | Double facer | set | 1 | Dryer part 600x9 block 4.5 meter,electrical rise and down of the press roller ,adopt concentration press roller ,oil-immersed lubricating |

| ZQS | High speed thin blade slitter | Set | 1 | Electrical rise and down ,electrical adjust deviation ,5 knives 8 creasing ,knives adopt the alloy steel |

| NC-80 | NC CUT OFF | set | 2 | Servo control straight knives style , kebi servo control motor ,and taiwan view touch screen 10.4 inch. |

| DMT-120 | Right angle stacker | set | 1 | Electrical adjust the board size ,and pueumatic control the cross feeding out the board |

| ZJ | Glue make system | 1 | 1 | Include two glue tanke of the diameter 800mm, tube buy by the client itself |

| QU | air system | set | 1 |

Include one 0.6m³air stock pot.air compressor Tube ready by buyer |

| ZQ | Steam heating | set | 1 | Steam system adopt the international standard ,,include the joint, allocator, steam trap valve ,gauge, boiler and tube ready by buyer. |

| DQ | Electrical control table | set | 1 | Electrical control system, all line speed adjust adopt the electrical magnetic motor ,main contator use the zhentai of delixi |

![]()