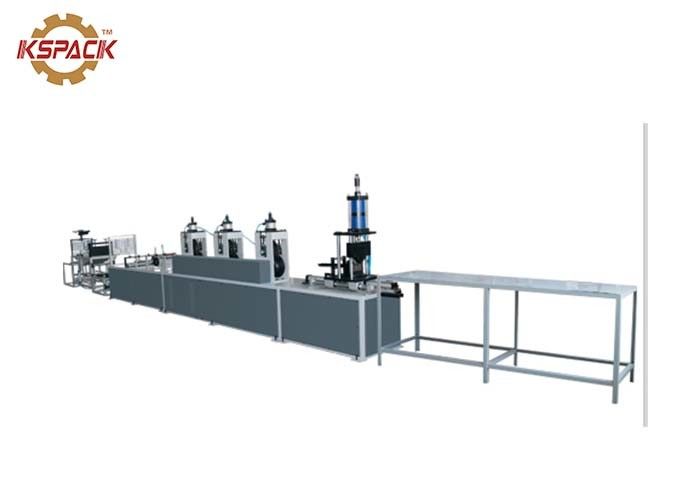

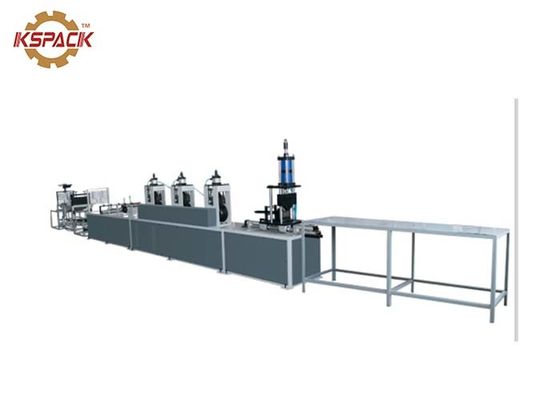

150 - 420GSM Automatic Paper Tube Making Machine Paper Corner Making Machine

-

Highlight

paper pipe making machine

,paper slitter rewinder machine

-

Machine NamePaper Corner Making Machine

-

Warranty Time1 Year

-

Material45 Steel

-

Motor5.5KW

-

Raw Material150-420GSM

-

Paper Corner Thickness1--8mm

-

Place of OriginHebei

-

Brand NameKSPACK

-

CertificationISO,CE

-

Model NumberKSHJ

-

Minimum Order Quantity1set

-

PriceNegotiable

-

Packaging Detailscontainer

-

Delivery Time30-50days after getting deposit

-

Payment TermsL/C, T/T, Western Union

-

Supply Ability15sets /month

150 - 420GSM Automatic Paper Tube Making Machine Paper Corner Making Machine

Automatic high speed paper corner making machine

2. The main electrical components of the implementation of CHINT products, cylinder components for the Austrian days Austrian products, these are China's well-known products. This product is durable, high practical value.

13. Paper on the part of the right-angle lifting on the paper holder. Right angle paper holder to save space, traction paper smooth, lifting the paper for the electric type, easy to operate, save labor.

14. Independent system for the plastic diaphragm pneumatic automatic glue. By adjusting the air pressure to control the speed of the plastic, the method is simple and easy to operate.

15. The main machine is composed of eight groups, the pressure roller depth of each molding device can be adjusted by manual adjustment of the cylinder (the cylinder is adjustable); the size of the pressure can be controlled by the pressure regulating valve according to the thickness of the corner guard Very easy.

16. Glue slot and glue tray for stainless steel products, there is corrosion resistance and wear resistance, greatly enhancing the service life of glue tank. Each layer of paper a separate glue tray to avoid the problem of easy to break the paper, scraping plastic bar for the step scraping plastic way, but also to solve the problem of paper break play an important role.

17. Cut off the corner of the conveyor device to facilitate the briquetting and transportation.

| technical parameter | |

| Paper corner specifications | Wide 80-150mm |

| 800-6000mm long | |

| Thick 1-8mm | |

| Production speed | 0-10 / min |

| monitor rate | 5.5kw |

| control method | Frequency |

| Raw materials | Faced paper 150g-200g |

| 300g-420g core paper | |

| Cutting method | Automatic cutting |

| Number of operators | 1-2 |

| Size (mm) | |

| Mainframe size: length * width * height | 4000*700*1400(mm) |

| Area: length * width | 18m*3m |

| Hub diameter | 310mm |

| Hub height | 176mm |

![]()