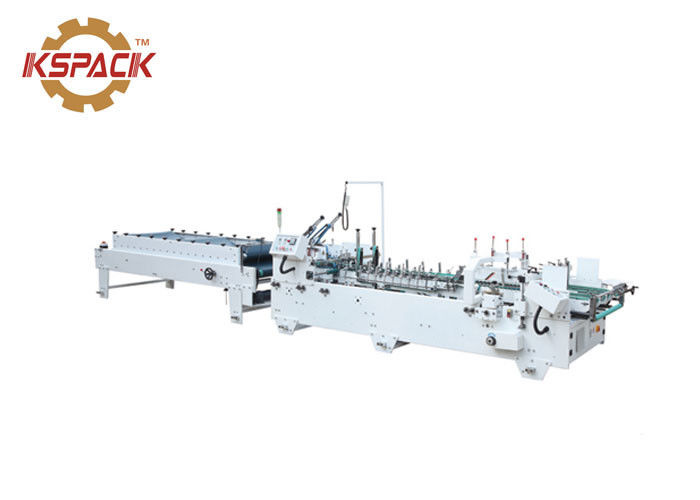

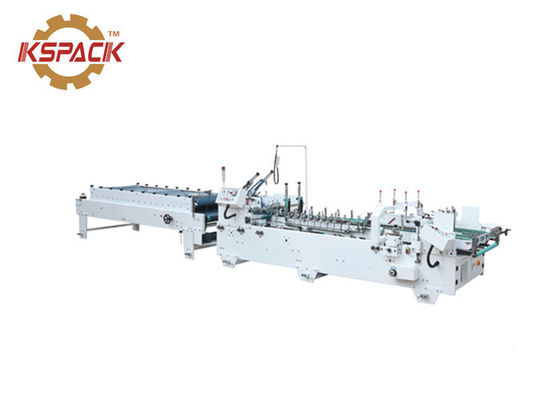

Automatic Small Cardboard Medicine Box Cosmetics Box Foler Gluer Machine

-

Highlight

carton folder gluer machine

,box folder gluer machine

-

Item NameAutomatic Small Cardboard Medicine Box Cosmetics Box Foler Gluer Machine

-

UsageSmall Box Forming Machine

-

Weight3000kg

-

FeatureEasy And Flexible Operation

-

Box StyleLock Bottom Box

-

Power7KW 380V

-

Place of OriginChina Hebei

-

Brand NameKingsun

-

CertificationCE

-

Model NumberKSHG

-

Minimum Order Quantity1 Set

-

PriceNegotiable

-

Packaging DetailsWrapped in plastic film and placed in wooden box

-

Delivery Time5-8 work days

-

Payment TermsL/C, T/T, Western Union

-

Supply Ability2 Set 40 per days

Automatic Small Cardboard Medicine Box Cosmetics Box Foler Gluer Machine

Automatic Small Cardboard Medicine Box Cosmetics Box Foler Gluer Machine

5. Working principle and adjusting method:

The fold of the paste box machine is folded and shaped according to the vein of paper box pressed trace. If the pressed trace is too shallow or the paper box is unaligned, the paste box machine can not fold the needed paper box, so before using the equipment, please carry out the check to the paper box sample plate. Take a sample plate to be held with hand slightly and then tighten the edge, have a check whether the pressed trace of the paper box is accurate. All unqualified pressed trace paper boxes are forbidden on this equipment.

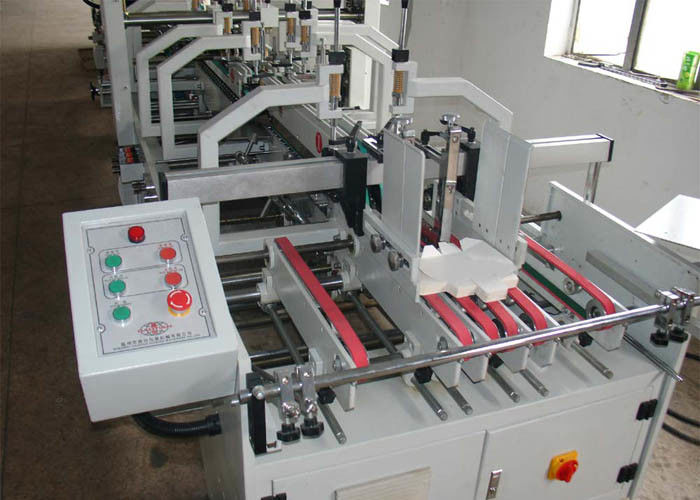

The paper feeding table is mainly in accordance with the paper sheet specification to adjust the distances between two gear paper plates, paper dividing gague position and paper out interval, make the paper convey successfully, steadily, not appear to any phenomenon of conveying double sheets, multi-sheets and no paper conveying. Adjustment method:

A. Adjust the distances between twp baffles according to the paper sheet width. First loosen the adjustable handle on the two baffles, put the paper sheets on the middle position of the paper sending table, move the two baffles approach towards the paper sheets, at the end adjust the two baffles and paper sheet both sides in parallel and remain a few space so as to let the paper sheets move in horizontal.

B. It’s necessary to carry out the adjustment to the paper dividing gague position according to the different size of the paper sheets needed to be pasted. In general the two paper dividing gague can be distributed evenly at the between of two baffles, the front and behind distances should be proper. When adjusting, only loosen the adjustable handle shown as Fig. 2, then move the slide block on the beam to left and right and paper dividing gague to front and behind, so as to make the paper dividing gague meet the desired position and then tighten the handle. Meanwhile, determine the conveying belt root number and make sure the paper sheets in level and tidy.

C. Adjust the interval δ between the paper dividing gague and conveying belt according to the paper sheet thickness. In general δ is the thickness of a piece paper. Adjustment method: Rotate the star-shape handwheel upward or downward, which can make the paper dividing gague move up and down so as to change the interval sizes.

6. Paste box size

SHH-800AG

| Type of boxex | Amax | Amin | Bmax | Bmin | Cmin | Dmin | Fmin |

| No-edged bottom box | 700mm | 700mm | 620mm | 110mm | 8mm | 70mm | 51mm |

| Edges bottom box | 700mm | 160mm | 570mm | 180mm | 9mm | 90mm | 85mm |

SHH-1200AG

| Type of boxex | Amax | Amin | Bmax | Bmin | Cmin | Dmin | Fmin |

| No-edged bottom box | 700mm | 110mm | 840mm | 110mm | 8mm | 70mm | 51mm |

| Edges bottom box | 700mm | 160mm | 790mm | 180mm | 9mm | 90mm | 85mm |